Custom Parts 3D Printing Service

Our Custom Parts 3D Printing Service offers precision manufacturing across diverse materials, including metals, plastics, ceramics, and resins, utilizing advanced technologies like SLA, SLS, DMLS, Binder Jetting, and more to meet your unique design and performance needs.

- Multi-material 3D Printing >>

- 3D printing Parts Case Study>>

- 3D Printing Industries Reference >>

- 36 Hours Fast Delivery >>

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Custom Parts 3D Printing Capabilities and Technologies

Our Custom Parts 3D Printing Capabilities and Technologies include advanced methods like FDM, SLS, SLA, and DMLS, supporting a wide range of materials. We deliver precise, functional components for diverse industries, tailored to meet specific design and performance requirements.

3D Printing Technologies

Our 3D Printing Process Solution offers cutting-edge technologies, including Material Extrusion, Powder Bed Fusion, and Directed Energy Deposition, enabling precision manufacturing, lightweight components, and optimized performance for aerospace, aviation, and other advanced industrial applications. Tailored to your unique needs.

3D Printing Materials Available At Neway

At Neway, we offer a diverse range of 3D printing materials, including superalloys, titanium, ceramics, stainless steel, carbon steel, copper, plastics, and resins. These materials provide high-performance solutions for prototyping, production, and specialized applications across industries.

Post Process for 3D Printed Components

Post-processing for 3D printed components includes techniques like CNC machining, EDM, heat treatment, HIP, TBC, and surface treatments. These processes improve dimensional accuracy, strength, surface finish, and durability, ensuring parts meet performance, aesthetic, and functional requirements for various applications.

3D Printed Parts Industries Applications

3D printed parts transform industries with rapid production, complex geometries, and material versatility. In aerospace and automotive, they enhance lightweight, high-strength components. Medical applications include implants and prosthetics. Consumer electronics benefit from precision prototyping, while architecture embraces intricate designs. Energy, robotics, and fashion industries leverage 3D printing for innovation, efficiency, and customized solutions across diverse applications.

Learn More

Rapid Prototyping

Learn More

Manufacturing and Tooling

Learn More

Aerospace and Aviation

Learn More

Automotive

Learn More

Medical and Healthcare

Learn More

Consumer Electronics

Learn More

Architecture and Construction

Learn More

Energy and Power

Learn More

Fashion and Jewelry

Learn More

Education and Research

Learn More

Sports and Recreation

Learn More

Robotics

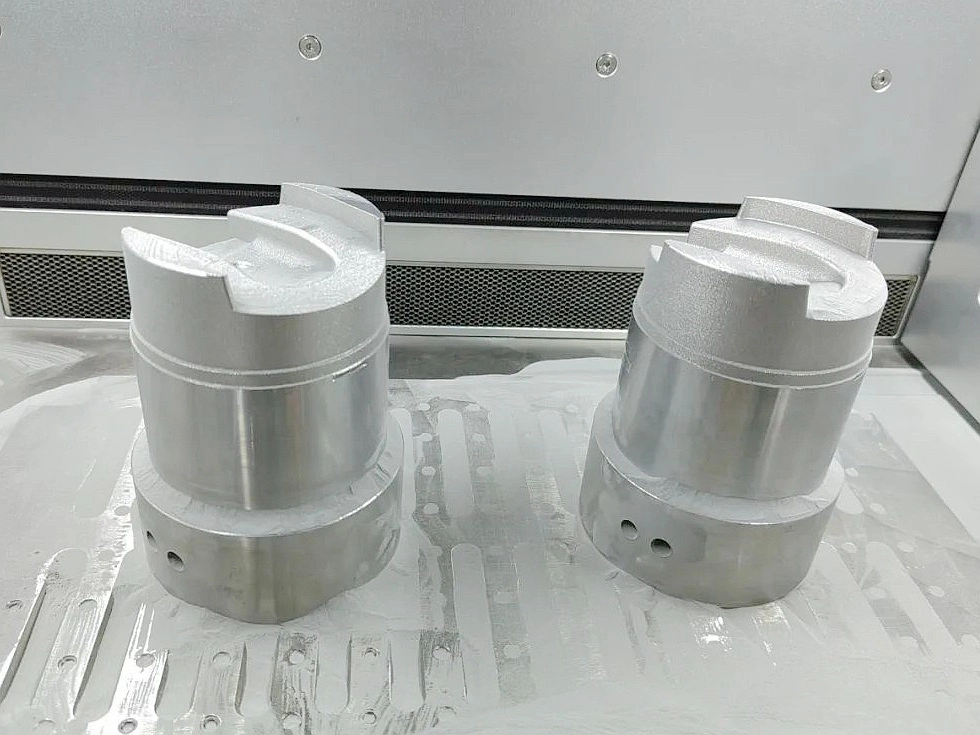

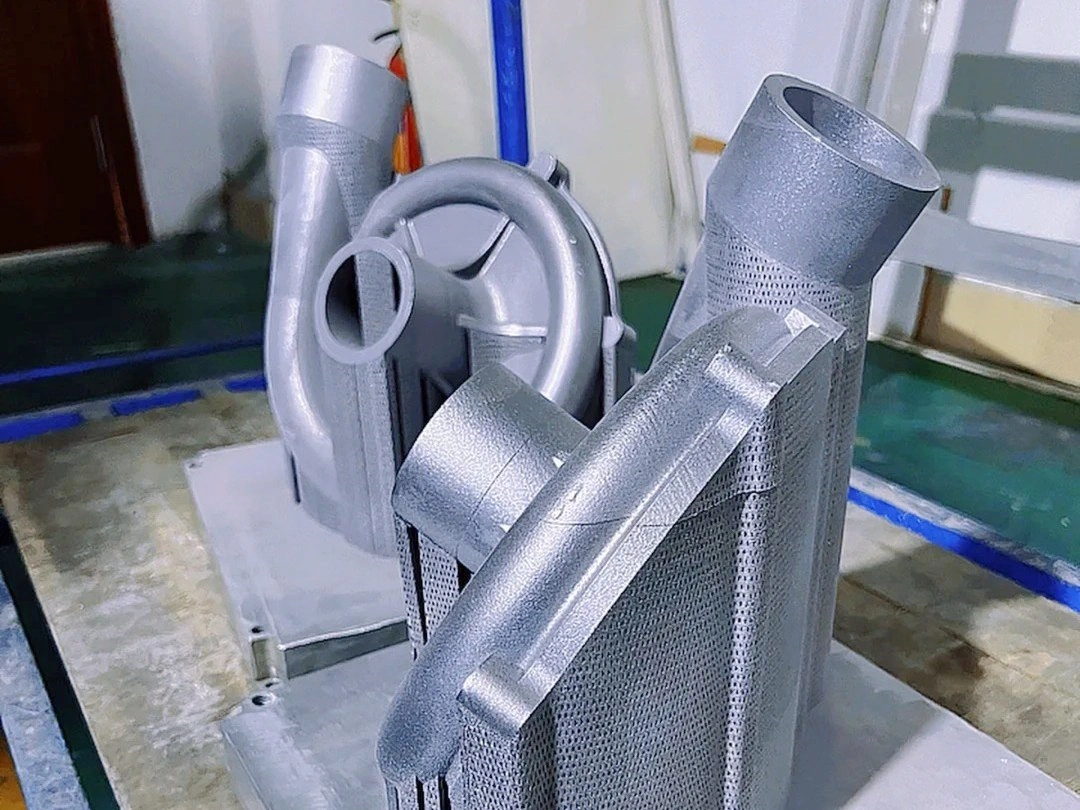

3D Printing Parts Gallery

The 3D Printing Parts Gallery showcases a diverse collection of custom parts created using various 3D printing technologies. Explore high-quality prototypes, functional components, and complex geometries across multiple industries, highlighting the versatility and precision of modern additive manufacturing techniques.

Let's Start A New Project Today

Explore Related Blogs

Explore Related Resources

Solutions

Copyright © 2026 3dp Precision Works Ltd.All Rights Reserved.