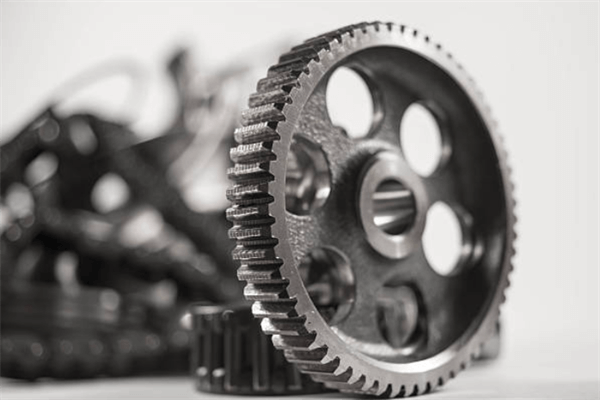

Carbon Steel Available In 3D Printing Service

Our 3D printing service offers a range of carbon steels, including Tool Steel D2, AISI 4130, AISI 4140, and 20MnCr5. These materials provide high strength, wear resistance, and durability, making them ideal for tooling, automotive, and industrial applications.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Carbon Steel 3D Printing Technologies

Carbon Steel 3D Printing Technologies, including DMLS, SLM, EBM, and Binder Jetting, produce strong, durable parts for various industries. These methods offer high precision, ideal for aerospace, automotive, and industrial applications, ensuring excellent mechanical properties and complex geometries.

Typical Carbon Used In 3D Printing

Carbon-based materials in 3D printing offer exceptional strength, lightweight properties, and heat resistance, making them ideal for aerospace, automotive, and industrial applications. Common types include carbon fiber-reinforced composites for high-strength, lightweight structures, graphene-enhanced materials for superior conductivity, and carbon nanotube-infused polymers for advanced mechanical performance. These materials enable durable, high-performance parts with enhanced thermal and electrical properties.

Let's Start A New Project Today

Tips for Choosing Right Carbon Steel In 3D Printing

Selecting the right carbon steel for 3D printing depends on your project's strength, wear resistance, and post-processing requirements. Tool steels provide high performance for cutting and molding applications, while grades like AISI 4130, 4140, and 20MnCr5 offer balanced strength and ductility for structural components. Consider tensile strength, yield strength, hardness, and density when choosing the appropriate carbon steel.