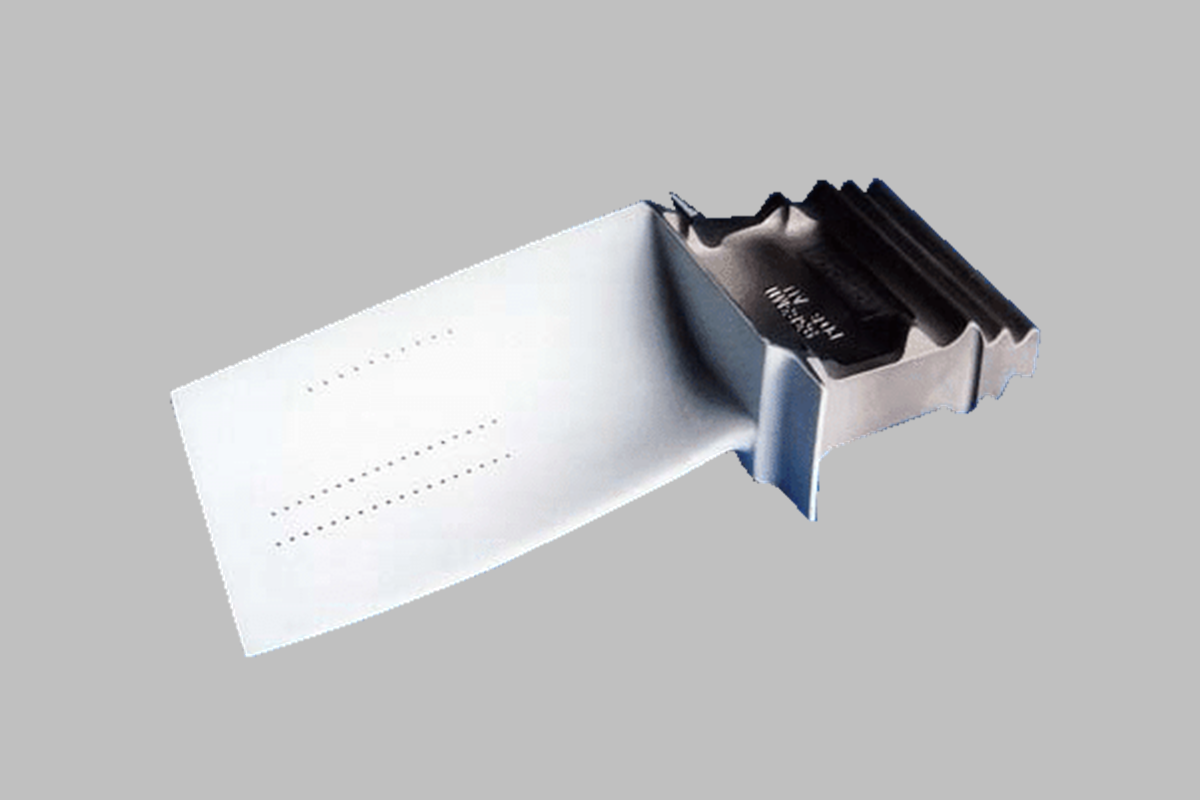

TBC Coating Service for 3D Printed Parts

TBC (Thermal Barrier Coating) service for 3D printed parts applies a protective coating to enhance heat resistance, durability, and surface protection. This process improves part longevity by reducing thermal stress and oxidation, making it ideal for high-temperature environments and demanding applications.

- Enhanced Heat Resistance: Protects parts from high temperatures.

- Improved Durability: Increases lifespan of 3D printed parts.

- Reduced Thermal Stress: Minimizes damage from temperature fluctuations.

- Better Surface Protection: Shields against oxidation and corrosion.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Benefits of TBC Coating on 3D Printed Parts

TBC (Thermal Barrier Coating) enhances 3D printed parts by providing superior heat resistance, improving durability, and reducing thermal stress. It also offers better surface protection against oxidation and corrosion, making parts more reliable and long-lasting in high-temperature, demanding environments.

Let's Start A New Project Today