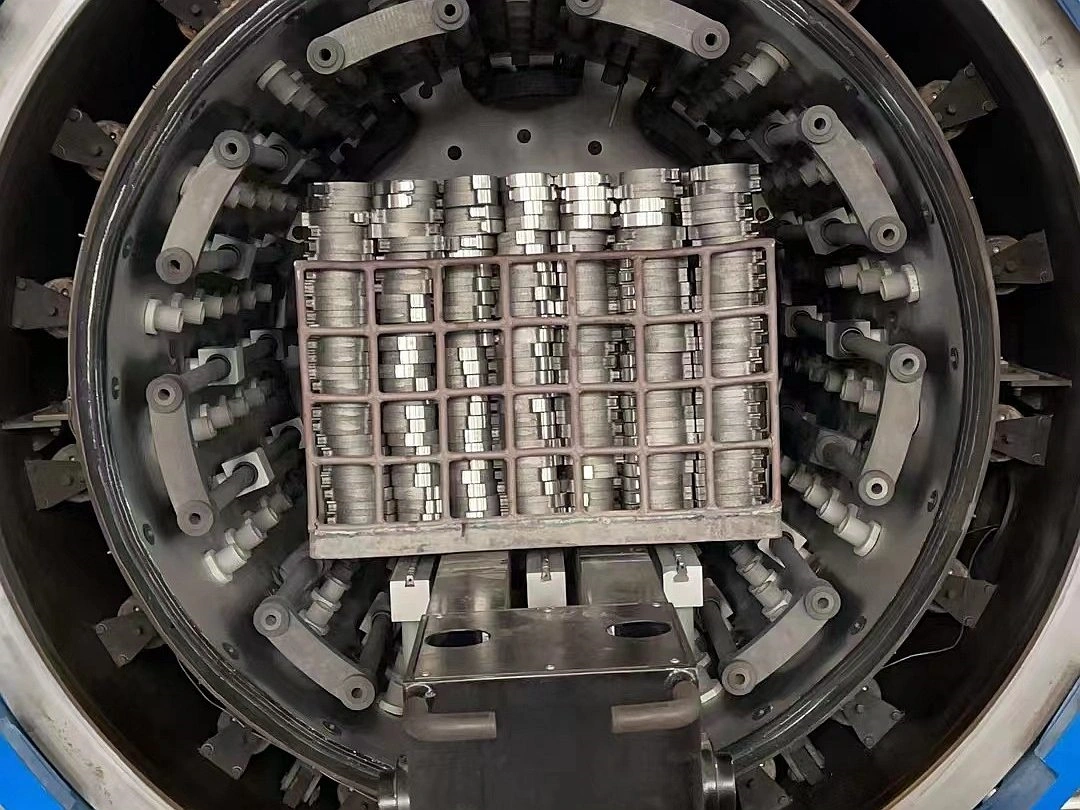

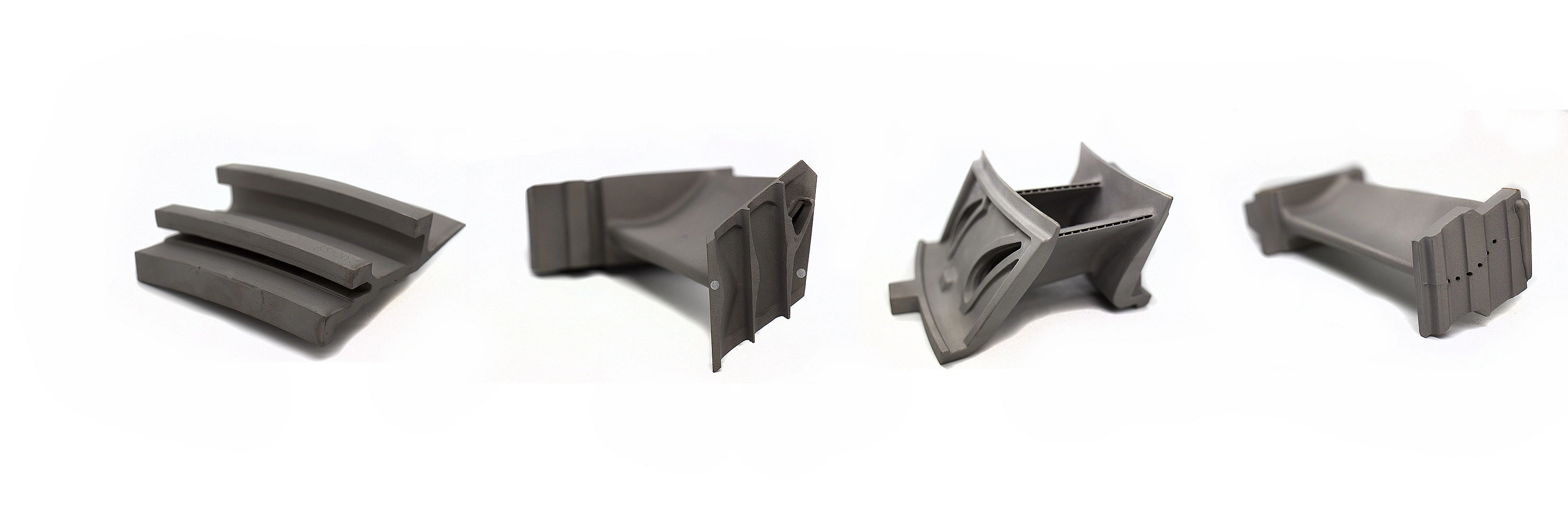

Heat Treatment Service for 3D Printed Parts

Heat treatment for 3D printed parts involves controlled heating and cooling processes that enhance material properties, such as strength, hardness, and durability. This service improves part performance by relieving internal stresses, increasing wear resistance, and ensuring long-term material stability for demanding applications.

- Improved Mechanical Properties: Increases strength, toughness, and hardness.

- Enhanced Durability: Boosts resistance to wear and fatigue.

- Stress Relief: Reduces internal stresses, preventing deformation.

- Better Material Stability: Ensures dimensional consistency over time.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Benefits of Heat Treatment on 3D Printed Parts

Heat treatment on 3D-printed parts improves mechanical properties by increasing strength, hardness, and toughness. It also enhances durability, wear resistance, and fatigue resistance. Additionally, it relieves internal stresses, prevents deformation, and ensures dimensional stability, making parts more reliable for high-performance and demanding applications.

Let's Start A New Project Today

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 3dp Precision Works Ltd.All Rights Reserved.