Ceramics Available In 3D Printing Service

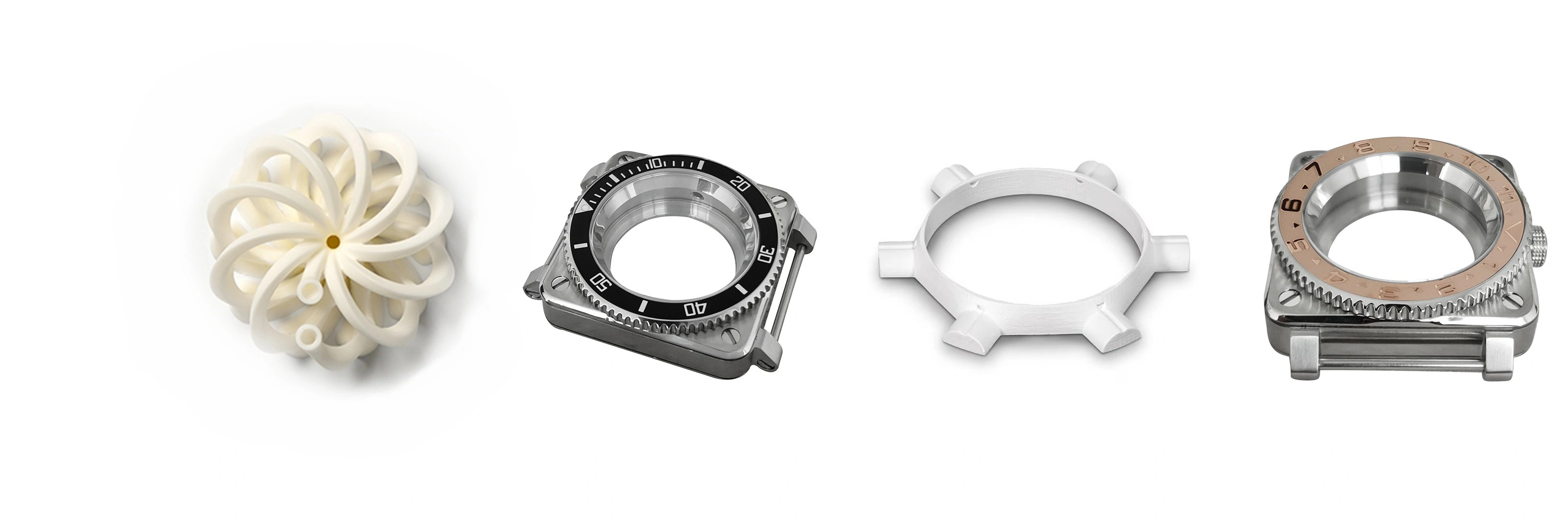

Our 3D printing service offers a diverse selection of ceramics, including Alumina (Al₂O₃), Zirconia (ZrO₂), Silicon Carbide (SiC), Hydroxyapatite (HA), and more. These ceramics provide exceptional heat resistance, wear resistance, and biocompatibility for advanced industrial, medical, and engineering applications.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

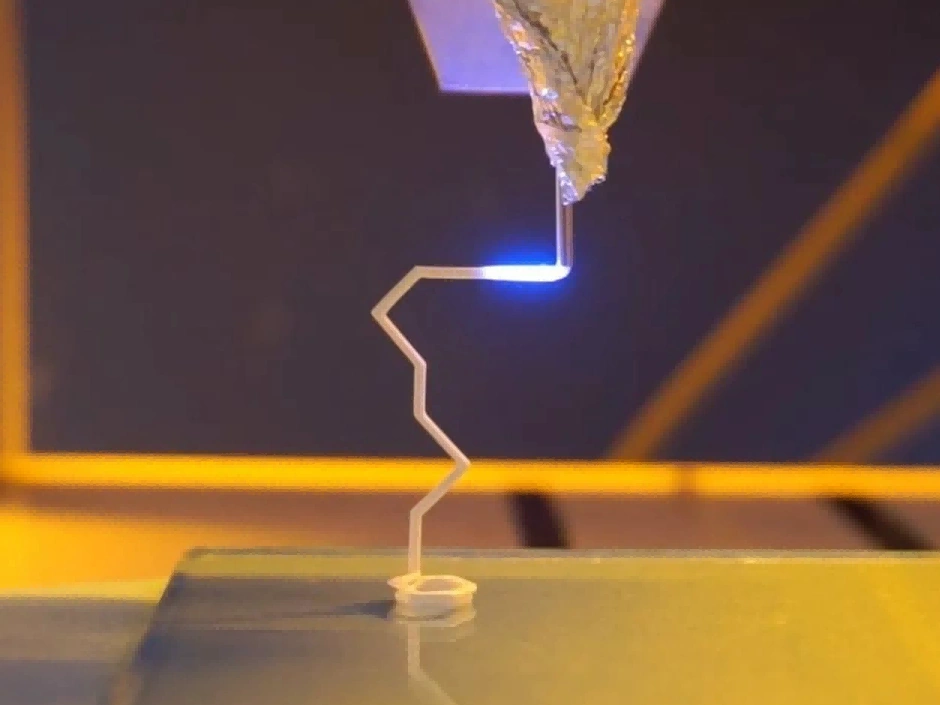

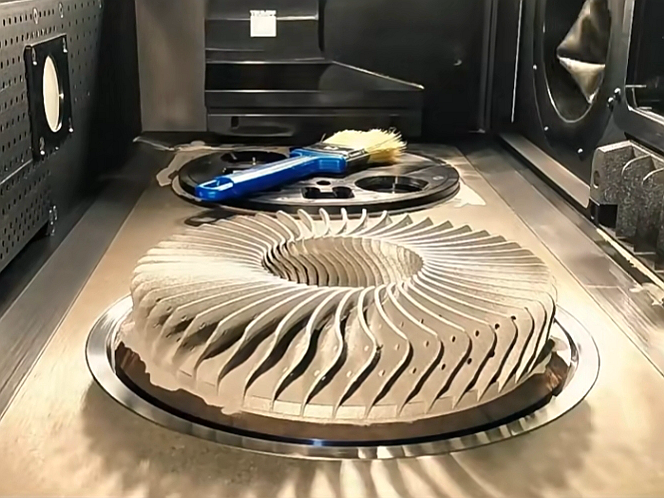

Ceramics 3D Printing Technologies

Ceramics 3D Printing Technologies, including SLS, MJF, and Binder Jetting, enable the creation of strong, durable ceramic parts with excellent mechanical properties. These processes offer high-speed production, support complex geometries, and eliminate the need for support structures or heat.

Typical Ceramic Used In 3D Printing

Ceramics used in 3D printing offer high-temperature resistance, electrical insulation, and exceptional hardness, making them ideal for aerospace, medical, and electronics applications. Common ceramics include alumina for wear resistance, zirconia for toughness, and silicon carbide for extreme heat tolerance. These materials enable complex, lightweight, and durable components in industries requiring precision and advanced thermal properties.

Let's Start A New Project Today

Tips for Choosing Right Ceramic Material In 3D Printing

Selecting the right ceramic material for 3D printing depends on the desired balance between strength, thermal stability, and wear resistance. Consider each ceramic's sintering requirements, brittleness, and post-processing needs to ensure optimal performance for your application.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 3dp Precision Works Ltd.All Rights Reserved.