Superalloys Available In 3D Printing Service

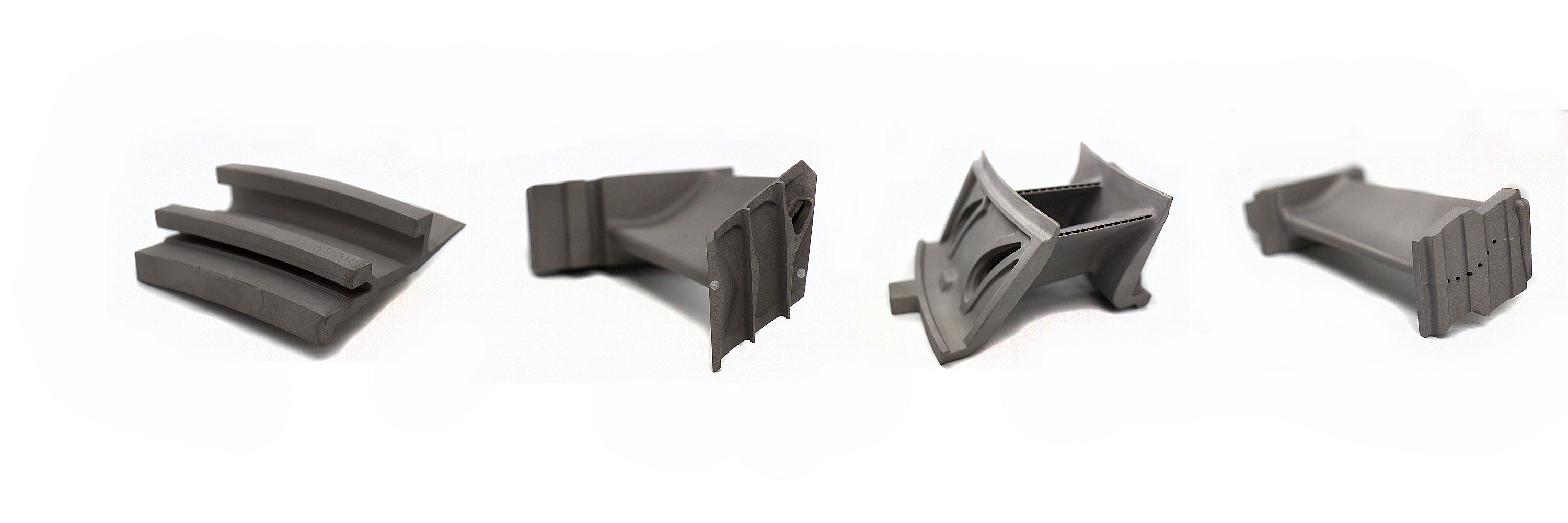

Our 3D printing service offers high-performance superalloys, including nickel-based, cobalt-based, and iron-based alloys. These materials provide exceptional strength, heat, and corrosion resistance, making them ideal for aerospace, energy, automotive, and industrial applications.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

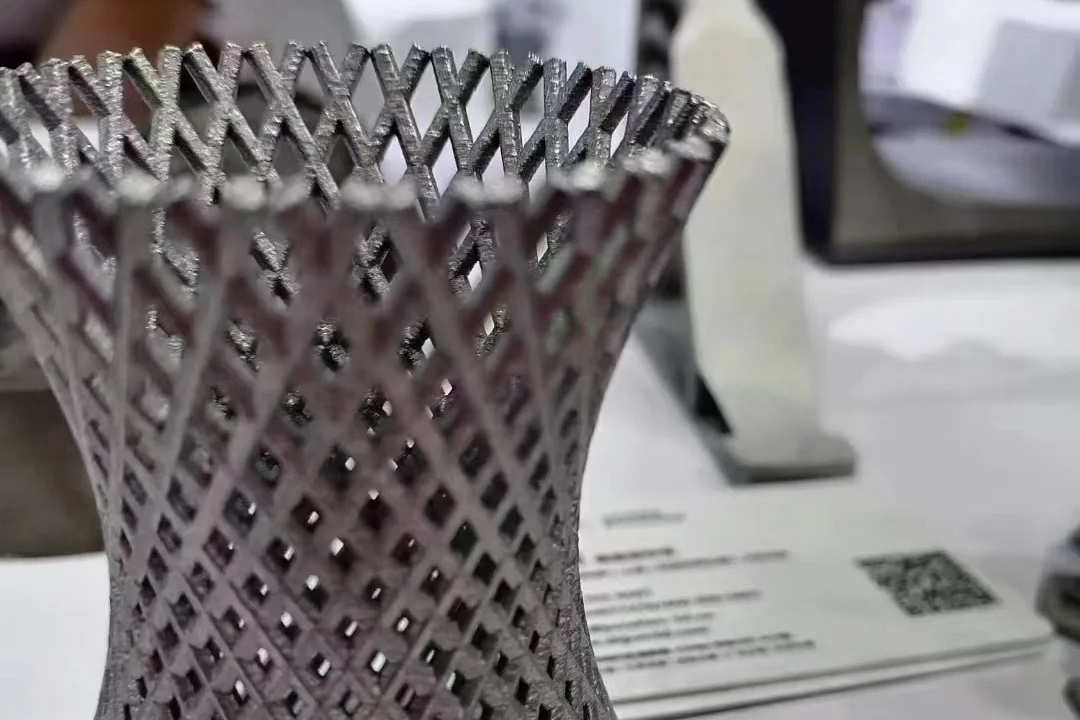

Superalloy 3D Printing Technologies

We utilize advanced technologies like Powder Bed Fusion, Binder Jetting, Directed Energy Deposition, and Sheet Lamination to produce high-quality superalloy components. These methods ensure precision, durability, and exceptional performance for aerospace, energy, automotive, and industrial applications.

Typical Superalloy Used In 3D Printing

Superalloys used in 3D printing offer exceptional heat, corrosion, and mechanical resistance, making them ideal for aerospace, energy, and high-performance applications. Common superalloys include Inconel 625 and 718 for extreme environments, Hastelloy for chemical resistance, and Haynes alloys for high-temperature strength. These materials enable complex, lightweight designs with superior durability in demanding industrial applications.

Let's Start A New Project Today

Tips for Choosing Right Superalloy In 3D Printing

Selecting the right superalloy for 3D printing depends on performance, temperature, and corrosion resistance requirements. Consider each alloy’s unique properties and printing parameters to achieve optimal performance for high-stress and high-temperature applications.