Resins Available In 3D Printing Service

Our 3D printing service offers a wide range of resins, including standard, tough, durable, flexible, high-temperature, dental, medical-grade, transparent, castable, UV-resistant, engineering, ceramic-filled, composite, sacrificial, and Formula 1μ resins, catering to diverse application needs.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Resins 3D Printing Technologies

Resins 3D Printing Technologies, including SLA, DLP, CLIP, and PolyJet, deliver high-resolution, smooth surface finishes for detailed prototypes. These methods enable fast printing speeds, continuous production, and multi-material capabilities, offering precision and versatility for various industries and applications.

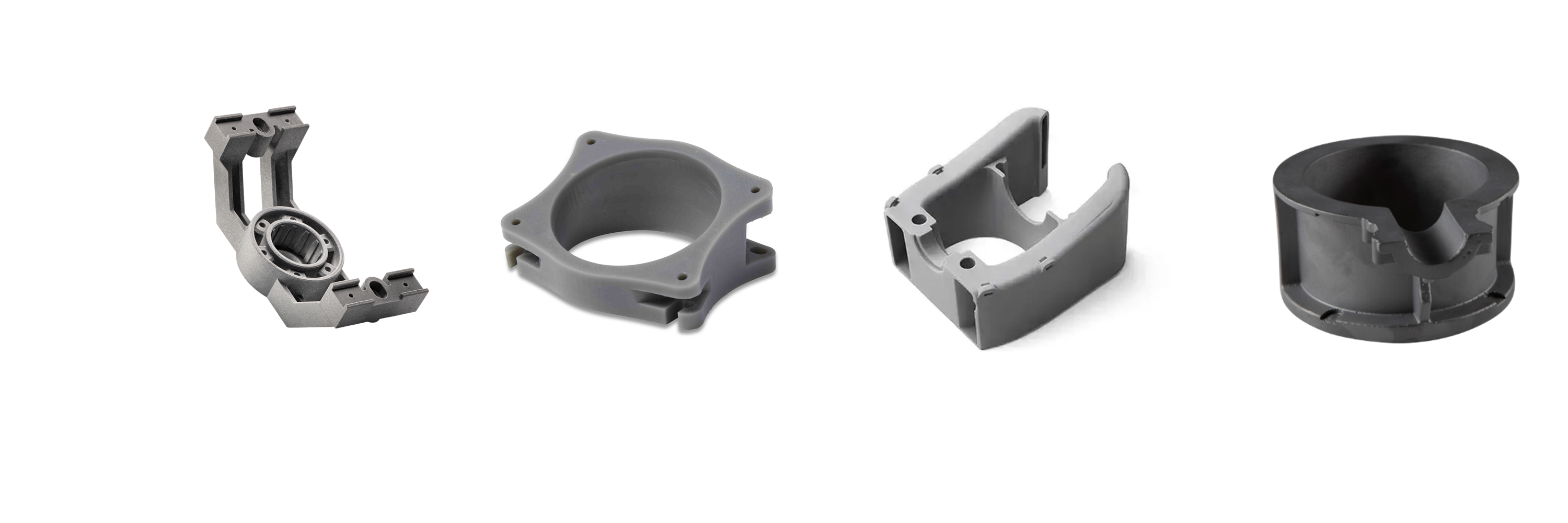

Typical Resin Used In 3D Printing

Resins used in 3D printing offer high detail, smooth finishes, and specialized properties for applications in prototyping, dentistry, and jewelry. Common types include Standard Resin for general prototyping, Tough Resin for impact resistance, Flexible Resin for elasticity, High-Temperature Resin for heat resistance, and Biocompatible Resin for medical and dental applications. These materials enable precise, durable, and highly functional 3D-printed parts.

Let's Start A New Project Today

How To Choose The Right Resins

Choosing the right resin depends on application needs. Standard resins suit general prototyping, tough resins offer durability, flexible resins provide elasticity, and high-temperature resins withstand extreme heat. Biocompatible resins are ideal for medical uses. Consider strength, flexibility, heat resistance, and precision to select the best resin for your 3D printing needs.