Titanium Alloy Available In 3D Printing Service

Our 3D printing service offers a wide range of titanium alloys, including Ti-13V-11Cr-3Al (TC11), Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI (Grade 23), and more. These high-performance alloys provide superior strength, corrosion resistance, and are ideal for aerospace, automotive, and medical applications.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Titanium Alloy 3D Printing Technologies

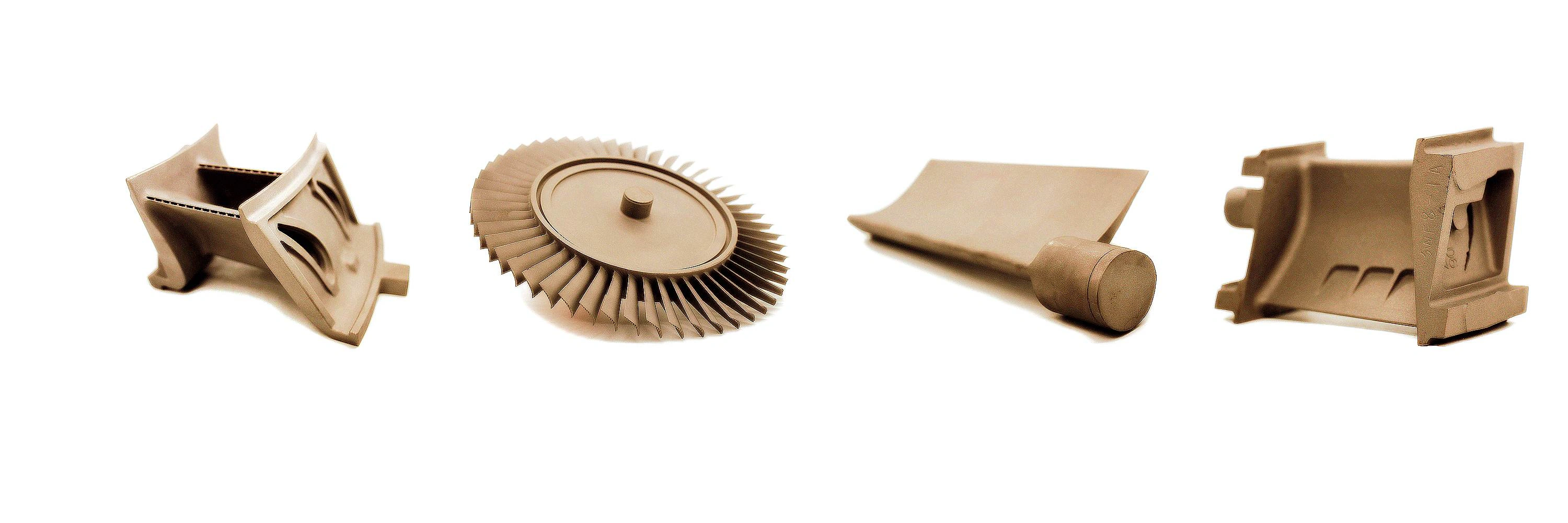

Titanium Alloy 3D Printing Technologies utilize advanced methods like DMLS, SLM, EBM, and more to produce high-strength, precise metal parts. These techniques ensure optimal performance for aerospace, automotive, and medical applications, offering durability, high density, and intricate geometries.

Typical Titanium Alloy Used In 3D Printing

Titanium alloys in 3D printing are prized for their high strength, low weight, and exceptional corrosion resistance. These properties make them ideal for aerospace, automotive, and medical applications. Common titanium alloys like Ti-6Al-4V offer excellent mechanical properties and are well-suited for producing complex structures requiring high performance under stress.

Let's Start A New Project Today

Tips for Choosing Right Titanium Alloy In 3D Printing

Selecting the right titanium alloy depends on performance, strength, and thermal requirements. Consider each alloy’s unique properties and 3D printing challenges to choose the optimal material for aerospace, biomedical, and high-performance engineering components.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 3dp Precision Works Ltd.All Rights Reserved.