CNC Machining Service For 3D Printed Parts

3D printed parts often require CNC machining post-processing to improve surface finish, enhance dimensional accuracy, and achieve tighter tolerances. This ensures the parts meet functional and aesthetic standards, particularly for high-performance applications where precision is critical.

- Improved surface finish

- Enhanced dimensional accuracy

- Stronger Structural Integrity

- Complex Geometry Refinement

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

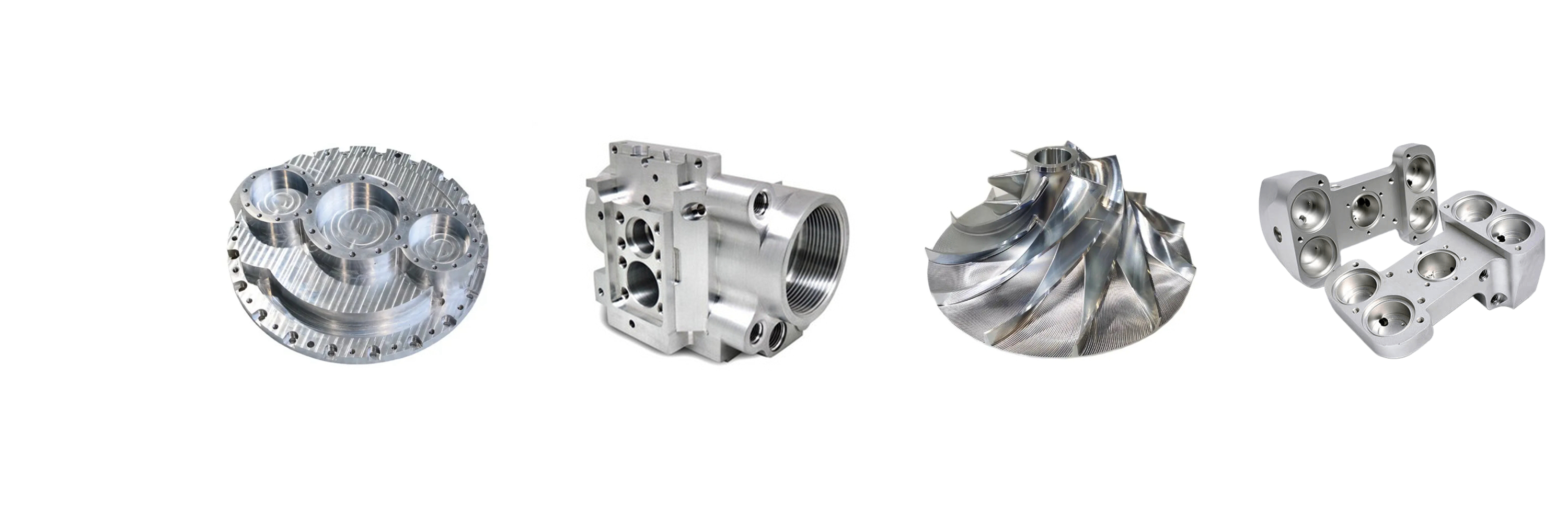

Our CNC Machining Capabilities For 3D Printed Parts

Our CNC machining capabilities for 3D printed parts include CNC milling, turning, drilling, boring, grinding, and multi-axis machining. We offer precision machining to refine part geometry, improve surface quality, and achieve tight tolerances for high-performance, custom applications.

Benefits of Post CNC Machining To 3D Printed Parts

Integrating CNC machining as a post-process for 3D printed parts can significantly enhance precision, surface finish, and overall quality. The table below outlines various CNC processes, their purposes, and the benefits they offer to refine additive manufactured components.

Let's Start A New Project Today