Hot Isostatic Pressing Service for 3D Printed Parts

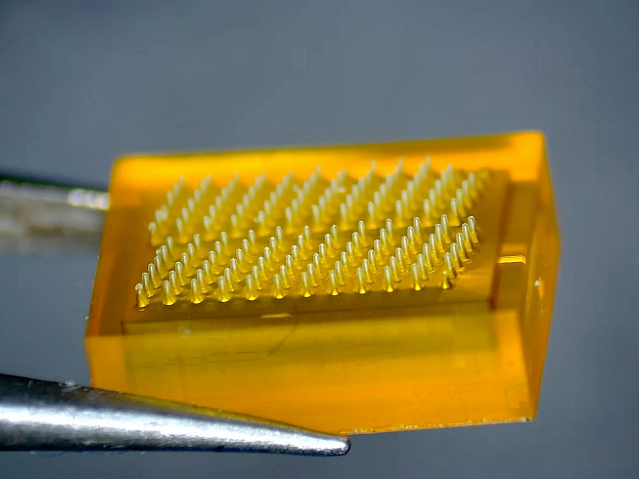

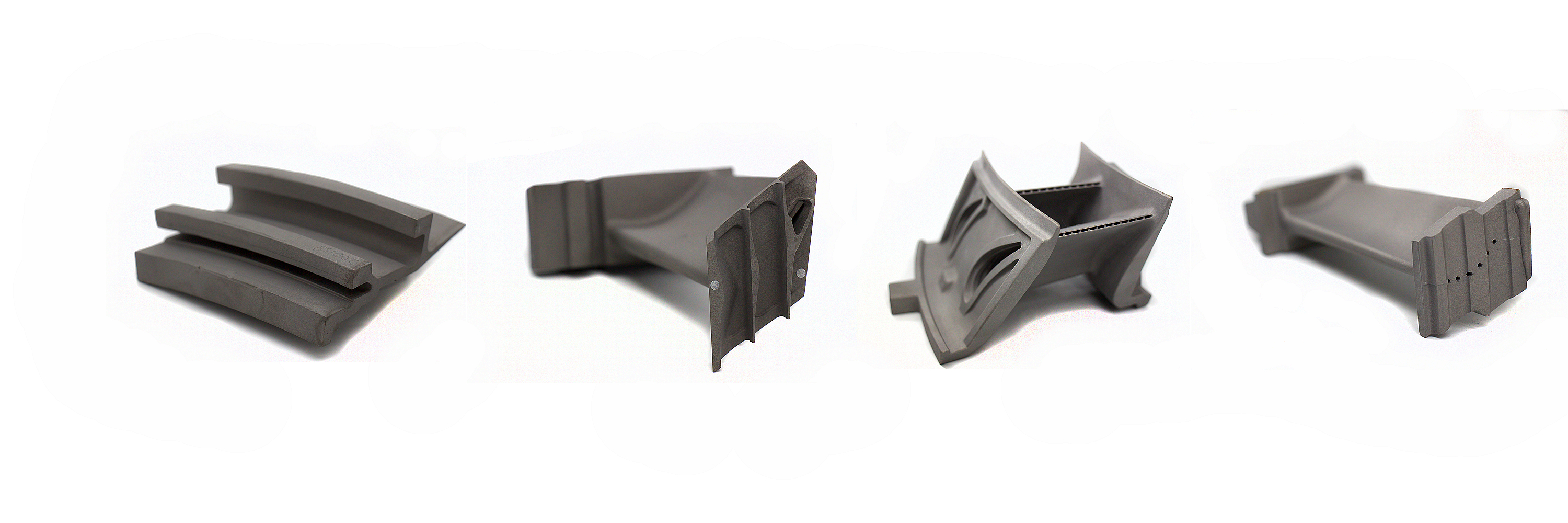

Hot Isostatic Pressing (HIP) service for 3D printed parts applies high temperature and pressure to eliminate internal porosity, enhance density, and improve mechanical properties. This process refines part strength, durability, and surface finish, ensuring better structural integrity and performance for critical applications.

- Increased Density: Eliminates internal porosity, enhancing strength.

- Improved Surface Finish: Enhances smoothness and appearance.

- Enhanced Mechanical Properties: Boosts strength and durability.

- Better Structural Integrity: Reduces cracks and voids effectively.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Benefits of HIP Process on 3D Printed Parts

The HIP process improves 3D printed parts by eliminating internal porosity, increasing density, and enhancing mechanical properties. It strengthens the material, refines surface finish, and ensures better structural integrity, making parts more durable, reliable, and suitable for high-performance applications.

Let's Start A New Project Today