Online Superalloy Parts 3D Printing Service

Leverage advanced Powder Bed Fusion, Binder Jetting, Sheet Lamination, and Directed Energy Deposition Additive Manufacturing technologies to produce high-performance superalloy components. Our online 3D printing service ensures precision, durability, and efficiency for aerospace, automotive, and industrial applications worldwide.

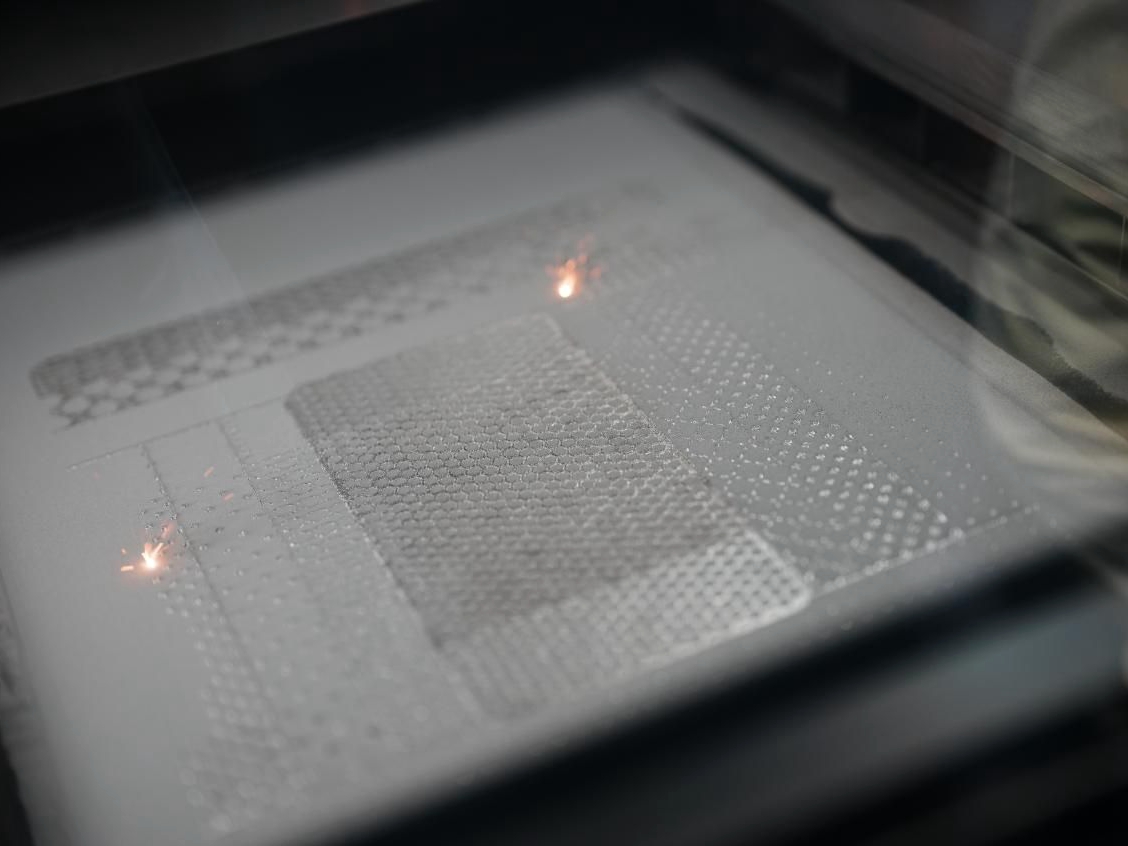

- Powder Bed Fusion 3D Printing

- Binder Jetting 3D Printing

- Sheet Lamination 3D Printing

- Directed Energy Deposition 3D Printing

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Superalloy 3D Printing Technologies

Harness the power of advanced additive manufacturing methods like Powder Bed Fusion, Binder Jetting, Directed Energy Deposition, and Sheet Lamination to produce high-performance, precision-engineered superalloy components for aerospace, automotive, and industrial applications with unmatched efficiency.

Superalloy 3D Printing Materials

Post Process for 3D Printed Superalloy Parts

Enhance performance and precision of superalloy components with CNC machining, EDM, heat treatment, HIP, TBC, and surface treatments. These processes optimize strength, durability, and functionality for demanding aerospace, industrial, and high-temperature applications.

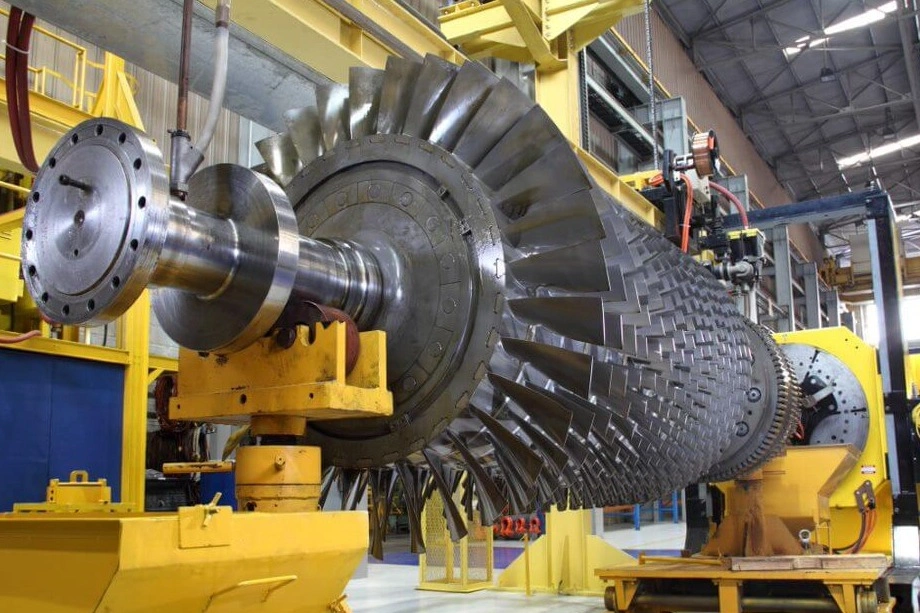

Applications of 3D Printed Superalloy Parts

3D printed superalloy parts excel in demanding industries like aerospace, power generation, and energy. Key applications include turbine blades, heat exchangers, corrosion-resistant valves, engine components, and high-temperature parts for critical industrial, automotive, and defense systems.

Case Study of Superalloy Parts 3D Printing

Leverage advanced 3D printing technologies, including Powder Bed Fusion and Directed Energy Deposition, and expertise in post-processing like HIP and TBC. Our precision-driven solutions deliver superior strength, durability, and performance for critical superalloy applications.

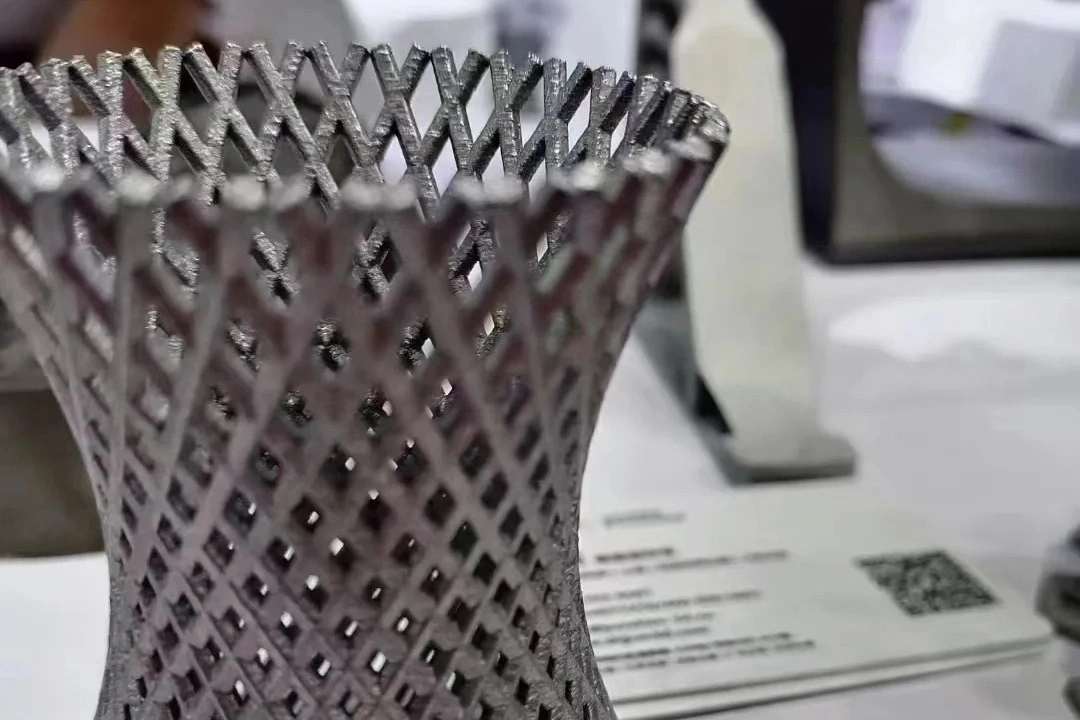

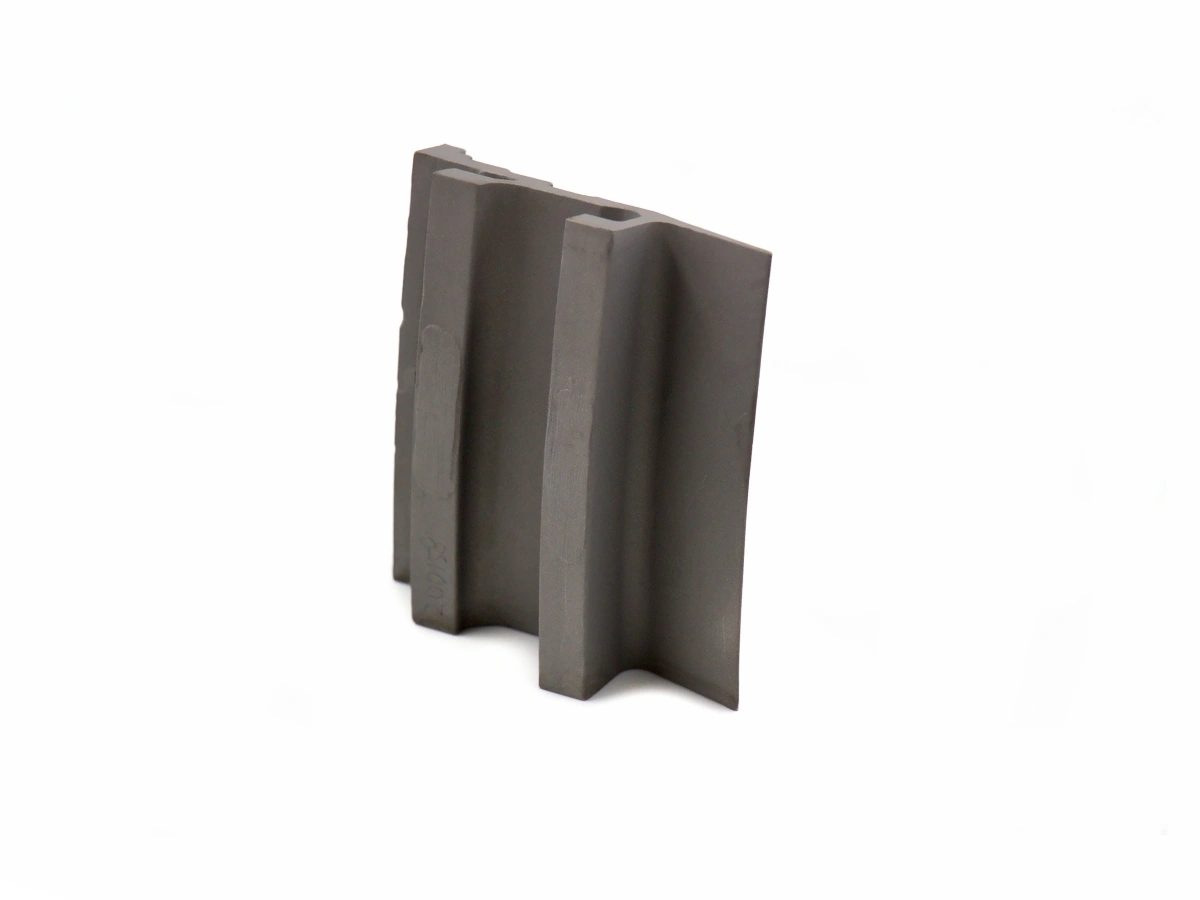

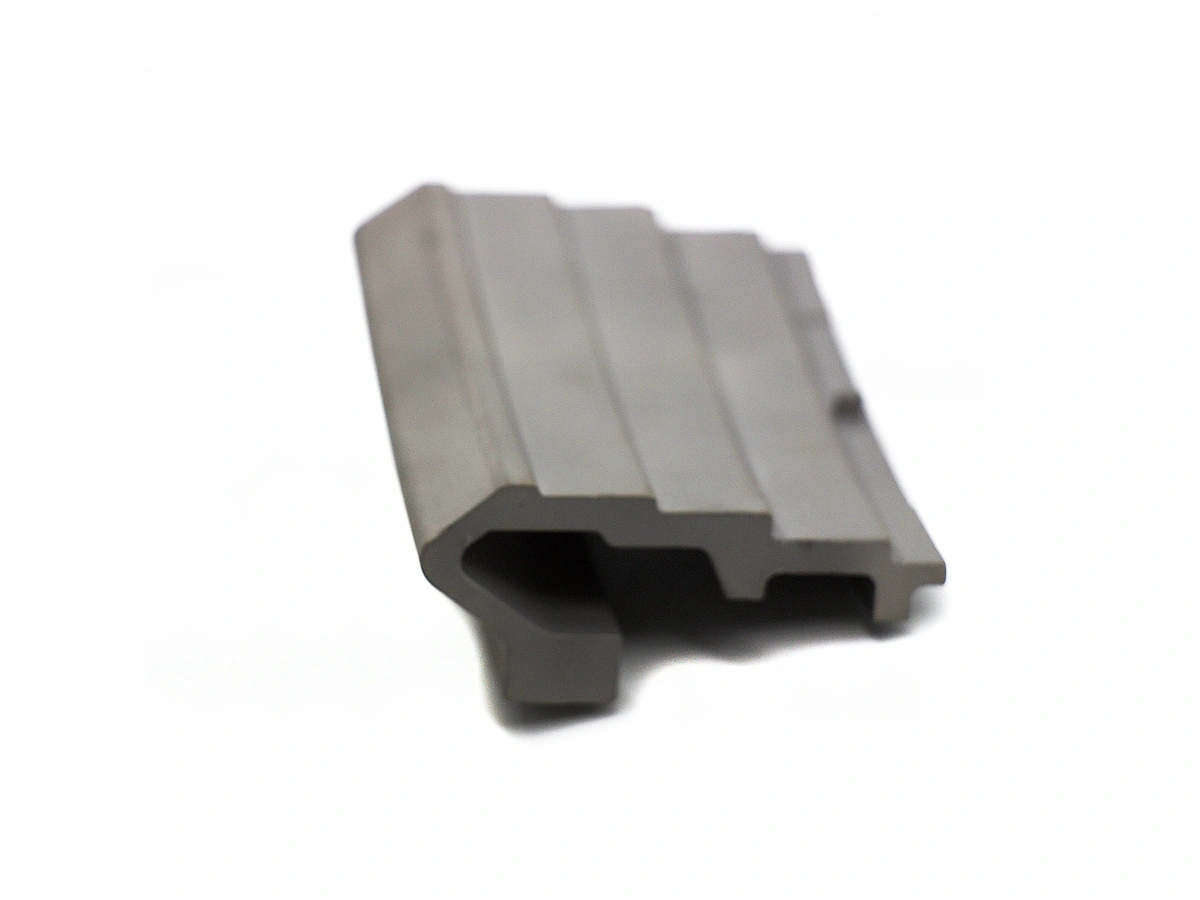

3D Printed Superalloy Parts Gallery

3D Printed Superalloy Parts Gallery showcases high-performance components designed for extreme environments. These parts, made from Inconel, Hastelloy, and Haynes alloys, offer exceptional heat, corrosion, and wear resistance. Used in aerospace, energy, and industrial applications, they demonstrate the precision, complexity, and durability achievable with advanced 3D printing technology for superalloy materials.

Let's Start A New Project Today

How to Select the 3D Printing Process for Superalloys

Consider part geometry, required mechanical properties, production scale, and cost. Match specific processes like SLS, DMLS, or EBM to your application’s precision, strength, and performance needs to achieve optimal results with superalloy materials.

Superalloy 3D Printed Parts Design Considerations

When designing superalloy 3D printed parts, consider wall thickness, tolerance, and hole design for structural integrity. Use supports for overhangs and optimize part orientation to enhance print quality. Implement thermal management strategies to reduce warping, efficiently incorporate lattice structures, and address stress concentrations with rounded features. Post-print heat treatments are crucial for stress relief and property enhancement.

Superalloy 3D Printed Parts Manufacturing Considerations

Manufacturing considerations for superalloy 3D printed parts are critical for applications requiring high temperature resistance and mechanical strength. Key factors include mastering high-temperature printing processes, controlling thermal stresses, and implementing post-processing techniques to achieve desired material properties and dimensional accuracy.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 3dp Precision Works Ltd.All Rights Reserved.