Online Powder Bed Fusion 3D Printing Service

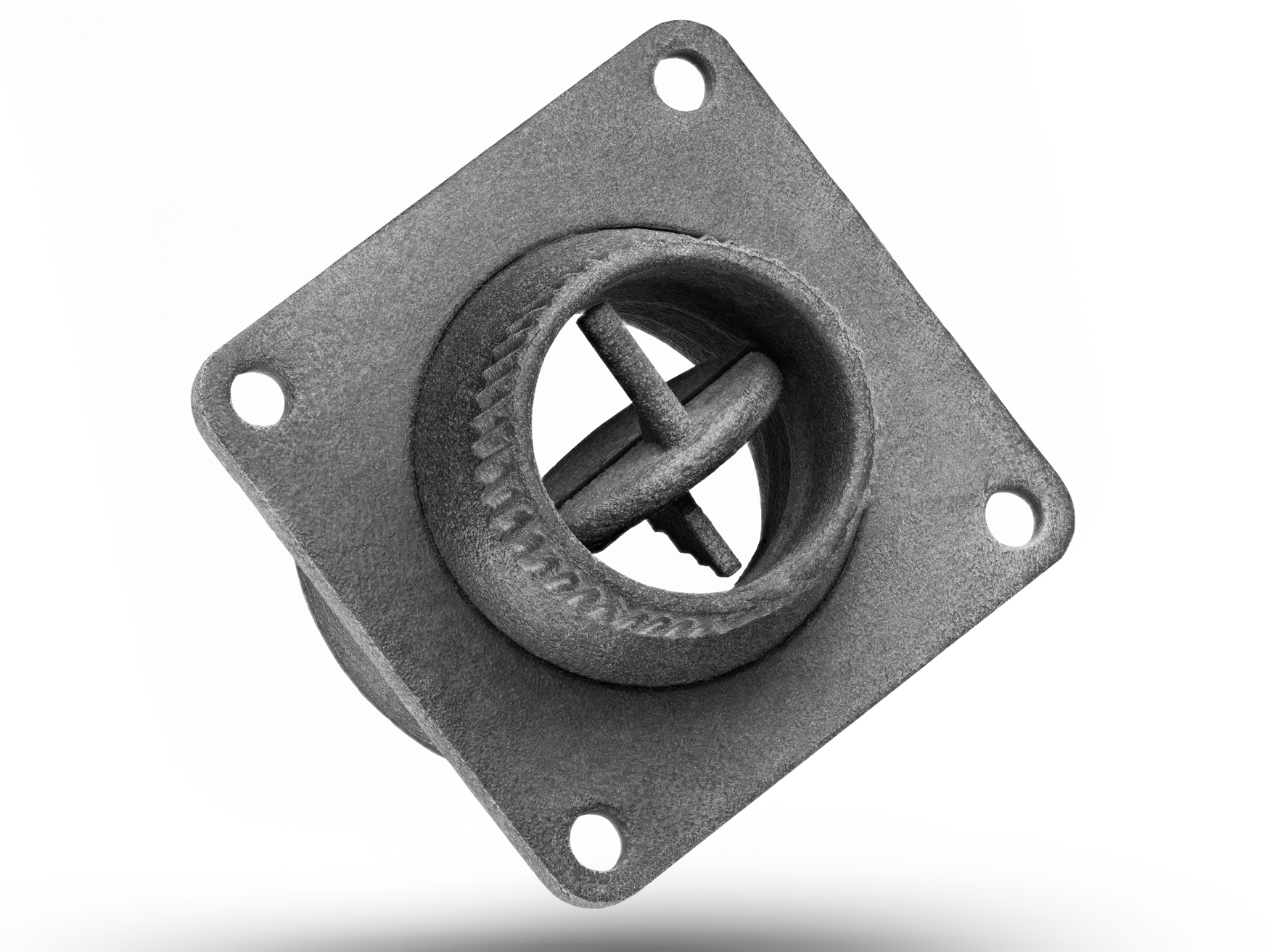

Our Online Powder Bed Fusion 3D Printing Service utilizes Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and Electron Beam Melting (EBM) technologies. These methods enable high-strength, complex parts with superior material properties for industrial applications and rapid prototyping.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Benefits of Powder Bed Fusion 3D Printing Service

Powder Bed Fusion 3D Printing Service employs a laser or electron beam to fuse powdered material layer by layer. This method produces highly detailed, durable parts with excellent mechanical properties, making it ideal for both prototyping and production of complex components.

SLS Vs. MJF Vs. DMLS Vs. SLM Vs. EBM

This comparison outlines the differences between Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and Electron Beam Melting (EBM) in terms of technology, materials, strength, accuracy, speed, surface finish, machine costs, and applications.

Let's Start A New Project Today

Powder Bed Fusion 3D Printed Parts Design Guideline

These design guidelines for powder bed fusion help optimize part performance by addressing critical aspects such as feature size, wall thickness, supports, orientation, and more. Following these recommendations improves precision, structural integrity, and overall print quality.