Carbon Steel Parts 3D Printing Service

Our Carbon Steel Parts 3D Printing Service delivers high-quality components using advanced techniques like DMLS, SLM, and Binder Jetting. Ideal for durable, precise, and customizable parts across industries, with post-processing options to meet your exact specifications.

- Powder Bed Fusion 3D Printing

- Binder Jetting 3D Printing

- Sheet Lamination 3D Printing

- Directed Energy Deposition 3D Printing

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Carbon Steel 3D Printing Technologies

Carbon steel 3D printing utilizes advanced technologies like DMLS, SLM, EBM, BJ, LMD, WAAM, and EBAM. These processes ensure precise, durable, and scalable parts for diverse applications, combining material efficiency, cost-effectiveness, and high-performance capabilities.

Carbon Steel 3D Printing Materials

Post Process for 3D Printed Carbon Steel Parts

Post-processing for 3D printed carbon steel parts enhances performance and durability. Techniques like CNC machining, EDM, heat treatment, HIP, TBC, and surface treatments ensure improved precision, strength, heat resistance, and aesthetics, meeting diverse industrial application requirements.

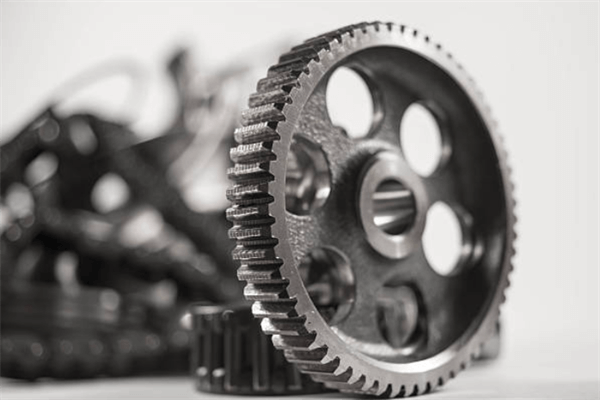

Applications of Carbon Steel 3D Printed Parts

Carbon steel 3D printed parts are known for their durability, strength, and cost-effectiveness, making them ideal for structural applications, tools, and custom machinery components. These parts are widely used across industries where robustness and high impact resistance are required.

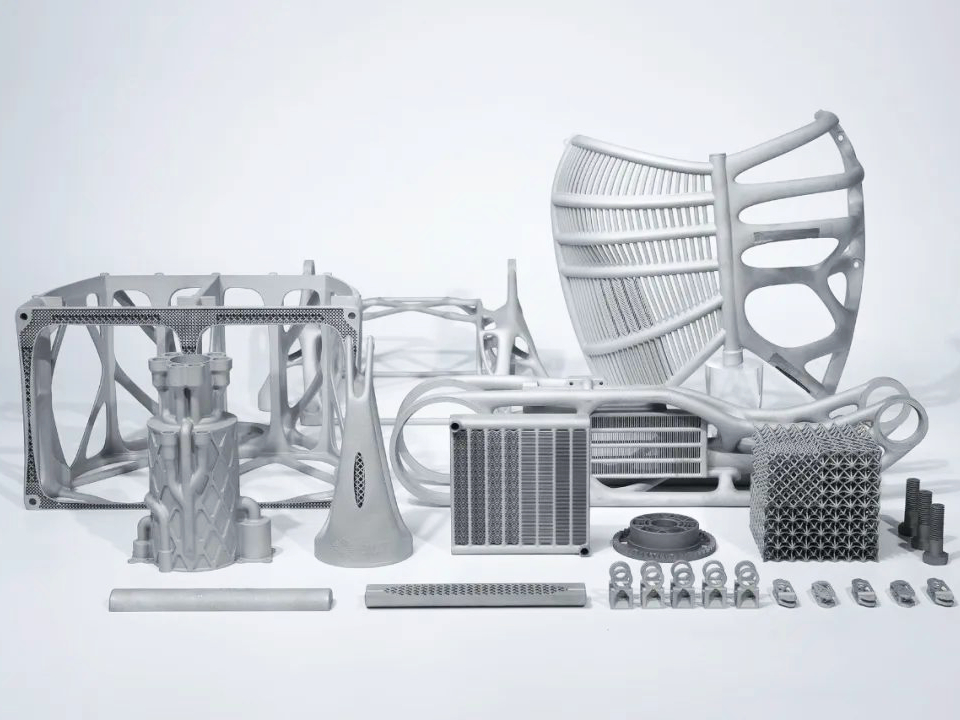

Carbon Steel 3D Printed Parts Case Study

This case study explores the transformative impact of carbon steel 3D printing across industries. From aerospace brackets to medical instruments, our advanced manufacturing solutions deliver high-strength, precision-engineered components. Discover how carbon steel 3D printing enhances durability, reduces weight, and accelerates innovation in automotive, energy, electronics, and more.

Let's Start A New Project Today

Carbon Steel 3D Printed Parts Design Considerations

Design considerations for carbon steel 3D printed parts focus on leveraging the material's durability and cost-effectiveness while managing issues like warping and rust. Effective design strategies include optimizing wall thickness, support structures, and post-processing to enhance the mechanical and surface properties of the final parts.

Carbon Steel 3D Printed Parts Manufacturing Considerations

Manufacturing considerations for carbon steel 3D printed parts focus on the material's properties such as strength and durability. Key aspects include managing thermal behavior during printing, optimizing part density, and ensuring surface finish quality. Post-processing plays a critical role in achieving desired mechanical properties and dimensional accuracy.