Stainless Steel Parts 3D Printing Service

Experience precision and innovation with our titanium parts 3D printing service. Utilizing Powder Bed Fusion, Binder Jetting, Sheet Lamination, and Directed Energy Deposition, we deliver high-quality, customized titanium components for diverse applications.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Stainless Steel 3D Printing Technologies

Stainless steel 3D printing technologies include SLS, DMLS, SLM, EBM, Binder Jetting, LMD, EBAM, and WAAM. These methods offer varying advantages such as high precision, strength, cost-effectiveness, and scalability, enabling complex geometries, large structures, and customized parts across industries like aerospace, medical, and manufacturing.

Stainless Steel 3D Printing Materials

Post Process for 3D Printed Stainless Steel Parts

Post-processing for 3D printed stainless steel parts enhances mechanical properties, dimensional accuracy, surface finish, and functionality. Techniques include CNC machining, heat treatment, HIP, EDM, coatings, and surface treatments, ensuring durability, precision, and suitability for diverse industrial applications.

Applications of Stainless Steel 3D Printed Parts

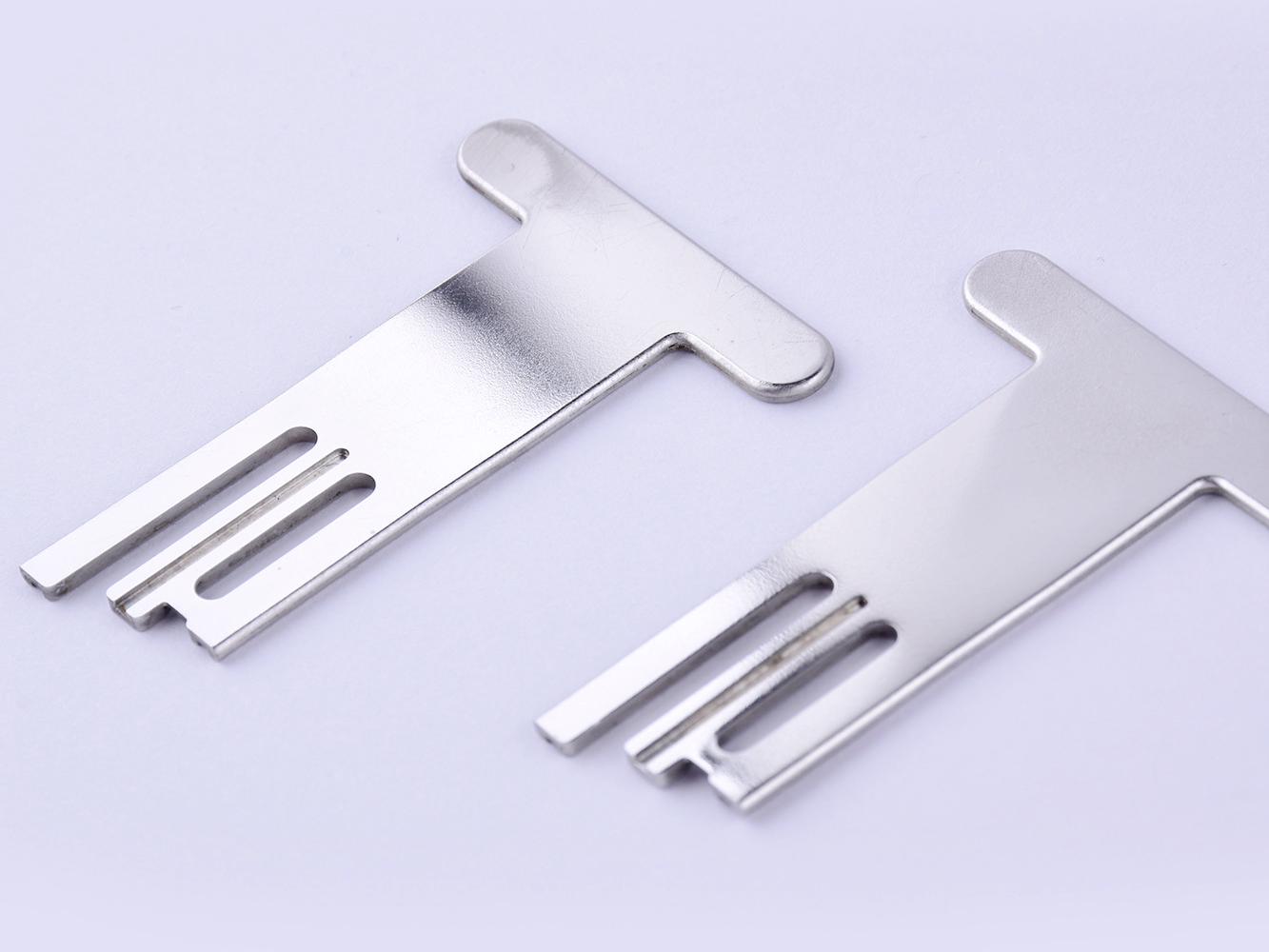

Stainless steel 3D printed parts are valued for their corrosion resistance, strength, and thermal properties. They are widely used in environments where both durability and aesthetic appeal are important. Key applications include functional prototypes, custom tools, and complex parts for the medical, aerospace, and automotive industries.

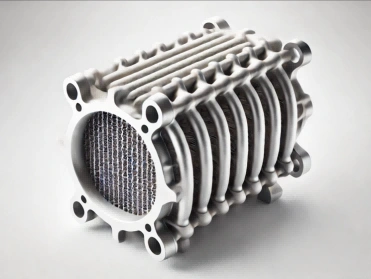

Stainless Steel 3D Printed Parts Case Study

Stainless Steel 3D Printed Parts Case Study showcases the versatility of stainless steel 3D printing across industries. From high-strength aerospace turbine blades to custom surgical instruments, wear-resistant automotive gears, and corrosion-resistant marine components, this study highlights how precision manufacturing enhances durability, performance, and customization in demanding applications like robotics, energy, and food processing.

Let's Start A New Project Today

Stainless Steel 3D Printed Parts Design Considerations

Designing stainless steel 3D printed parts involves specific considerations to ensure mechanical integrity and optimal surface finish. Stainless steel's high strength and corrosion resistance make it ideal for complex parts, but it requires careful handling of thermal stress and support structures during printing.

Stainless Steel 3D Printed Parts Manufacturing Considerations

Manufacturing considerations for stainless steel 3D printed parts are crucial to capitalize on the material’s corrosion resistance and strength. Key factors include controlling the printing environment, optimizing print parameters for density and structural integrity, and meticulous post-processing to achieve the desired surface finish and mechanical properties.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2026 3dp Precision Works Ltd.All Rights Reserved.