Custom Online Resin 3D Printing Service

Experience precision and versatility with our Custom Online Resin 3D Printing Service. Offering high-quality printing in various resin types, we specialize in producing durable, detailed, and functional parts for diverse applications, ensuring fast turnaround and professional results every time.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Resin 3D Printing Technologies

Resin 3D printing technologies like SLA, DLP, CLIP, PolyJet, and MMJ deliver high precision, smooth finishes, and versatility. They excel in creating detailed prototypes, functional parts, and multi-material designs with liquid photopolymer resins, ensuring exceptional quality and speed.

Resin 3D Printing Materials

Applications of 3D Printed Resin Parts

3D printed resin parts are celebrated for their fine detail, smooth surfaces, and versatility in applications requiring high accuracy and aesthetics. These parts are extensively used in industries such as jewelry, dental, and consumer electronics, where detail and finish quality are critical.

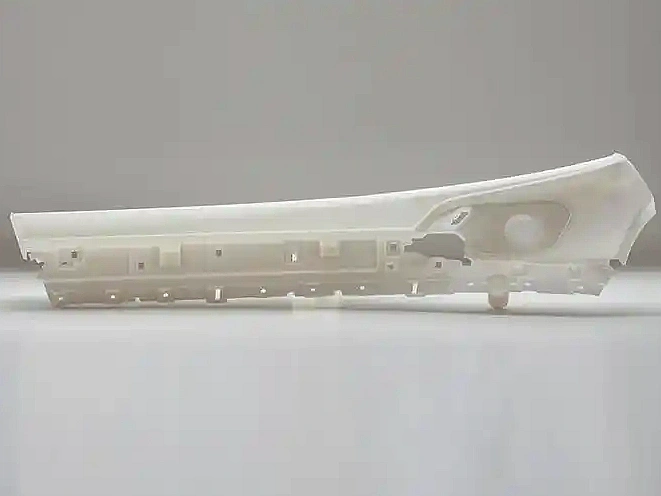

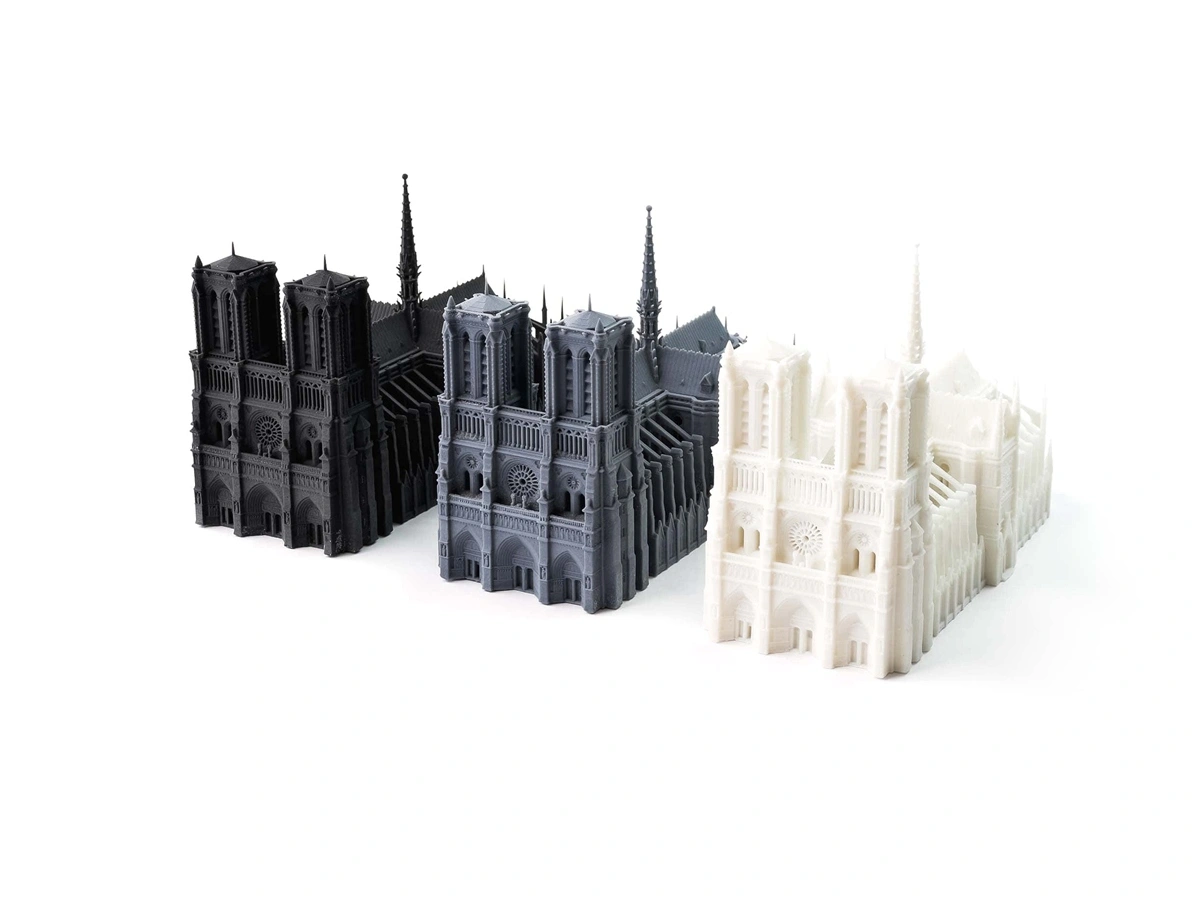

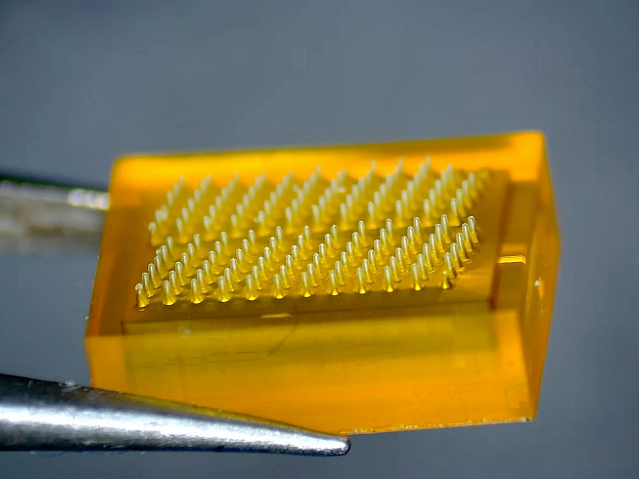

Resin 3D Printed Parts Gallery

Discover the precision and versatility of resin 3D printing through our curated gallery. From high-detail automotive prototypes to biocompatible medical models, sleek consumer electronics, and intricate jewelry, resin printing elevates design and functionality. Explore ultra-precise, smooth-finish parts transforming industries like robotics, architecture, fashion, and education with cutting-edge innovation.

Let's Start A New Project Today

Resin 3D Printed Parts Design Considerations

Resin 3D printing, known for its high detail and smooth finishes, requires careful attention to detail in design to mitigate issues such as warping and post-curing deformation. Design considerations should focus on structural integrity, curing times, and chemical resistance, especially for functional parts exposed to light or heat.

Resin 3D Printed Parts Manufacturing Considerations

Manufacturing considerations for resin 3D printed parts are critical for achieving optimal results. This includes selecting the right resin material, managing texture and surface roughness, and implementing controls for precision, layers, shrinkage, and warp. Post-processing plays a significant role in final part quality, affecting the mechanical properties and appearance of the printed objects.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 3dp Precision Works Ltd.All Rights Reserved.