Vat Photopolymerization 3D Printing Service

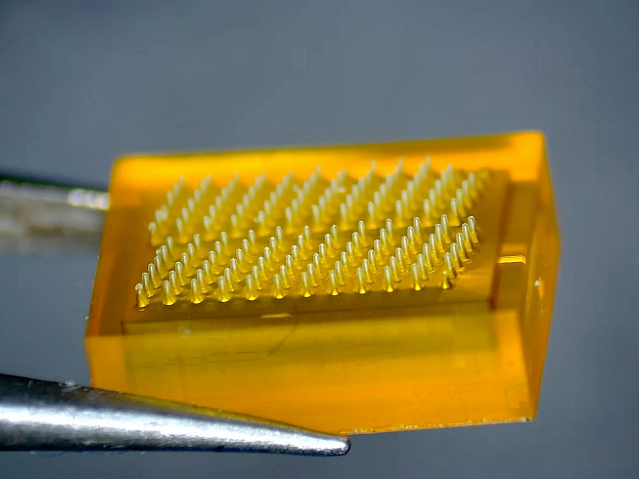

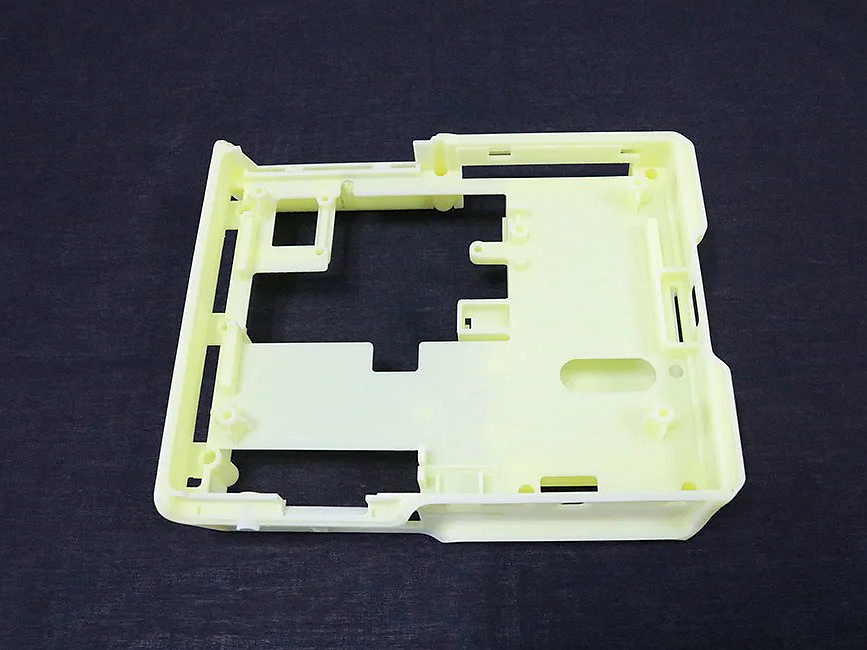

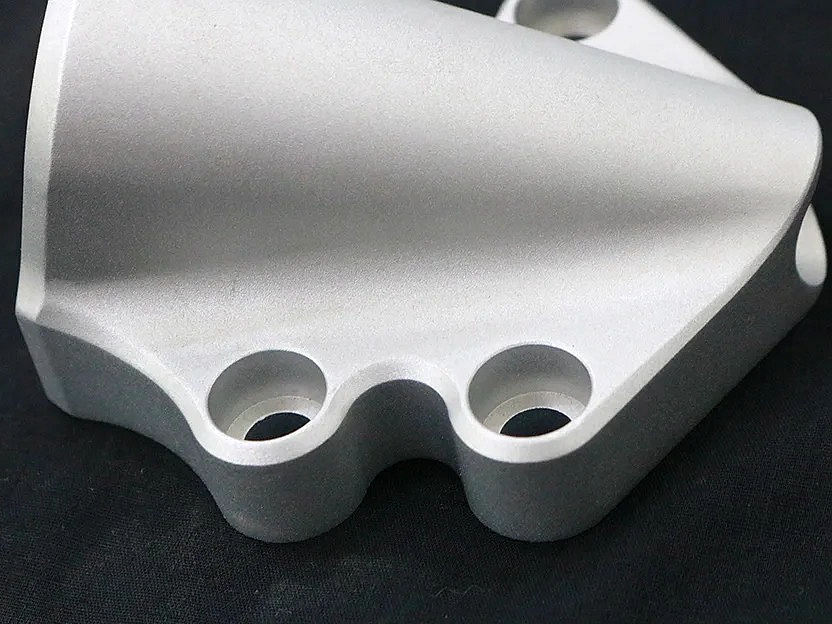

Our Online Vat Photopolymerization Service leverages Stereolithography (SLA), Digital Light Processing (DLP), and Continuous Liquid Interface Production (CLIP) technologies. These methods deliver high-precision, detailed prints with smooth surface finishes, ideal for intricate prototypes and end-use parts in industries requiring fine resolution and accuracy.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Benefits of Vat Photopolymerization 3D Printing Service

Vat Photopolymerization 3D Printing Service utilizes a vat of photopolymer resin that is selectively cured layer by layer using a light source. Commonly known as SLA or DLP, it offers high resolution, intricate details, and smooth finishes—perfect for prototypes, detailed models, and functional parts.

SLA Vs. DLP Vs. CLIP

A comparison of three popular resin-based 3D printing technologies: Stereolithography (SLA), Digital Light Processing (DLP), and Continuous Liquid Interface Production (CLIP). This table outlines key aspects such as technology, speed, accuracy, materials, strength, surface finish, machine costs, operational complexity, and typical applications.

Let's Start A New Project Today

Vat Photopolymerization 3D Printed Parts Design Guideline

These design guidelines help optimize parts for vat photopolymerization 3D printing. They address critical aspects such as minimum feature size, wall thickness, supports, orientation, drainage, clearance, layer height, post-curing, aspect ratio, text details, hollowing, surface finish, and tolerance to ensure high-quality, robust prints.