Sports and Recreation Parts Prototyping

Sports and Recreation Parts 3D Printing Service

Boost your sports and recreation performance with our expert 3D printing service! We craft durable, high-quality parts—ranging from custom grips to robust equipment. Enhance precision, functionality, and design for your gear. Start creating with us today!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Less Waste, More Innovation!

- Faster Prototypes, Smarter Solutions!

3D Printing in Sports and Recreation

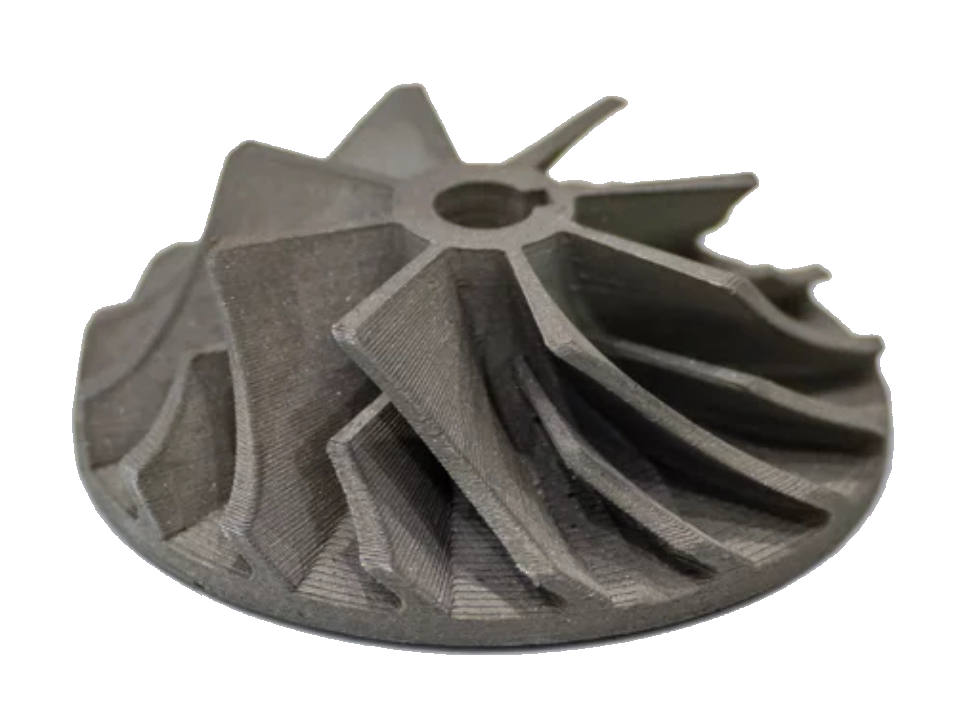

3D Printing in Sports and Recreation enhances performance and customization by producing lightweight, durable equipment and gear. It enables the creation of personalized footwear, protective gear, and high-performance components using advanced materials like carbon fiber composites and flexible polymers. This technology optimizes design, reduces weight, and improves functionality for athletes and enthusiasts alike.

Benefits of 3D Printing In Sports and Recreation

3D printing in sports and recreation empowers innovation by enabling customized equipment, innovative design exploration, rapid prototyping, and enhanced safety features. This technology transforms sports gear development, driving improved performance, protection, and tailored experiences for athletes.

3D Printing Material Solution for Sports and Recreation

Elevate sports and recreation with cutting-edge 3D printing materials! From lightweight titanium to durable plastics, we offer custom solutions for gear, equipment, and accessories. Unleash performance, precision, and style with our innovative material expertise. Contact us today!

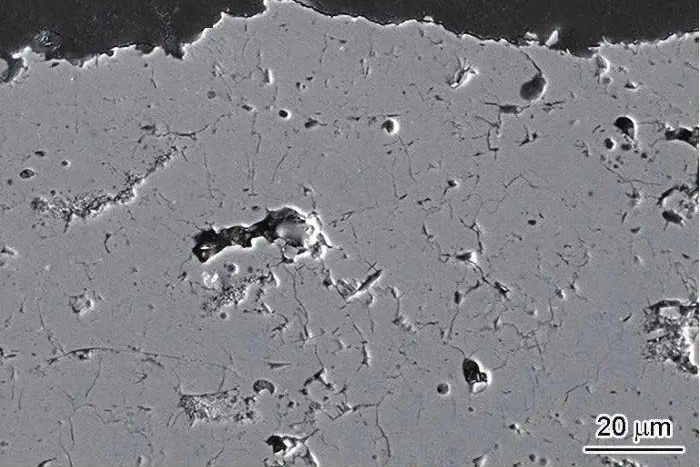

Post Process for 3D Printed Sports and Recreation Parts

Post-processing plays a crucial role in enhancing the performance and durability of 3D printed sports and recreation parts. Techniques like CNC machining, EDM, heat treatment, and surface treatments refine designs, improve material properties, and ensure optimal functionality for high-performance gear.

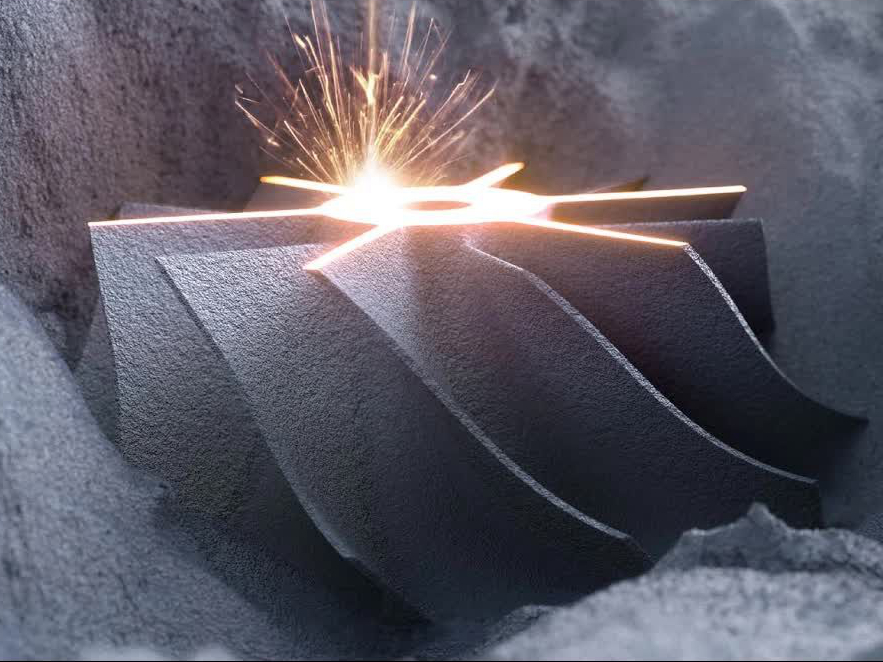

3D Printing Process Solution

.

Case Study

Let's Start A New Project Today