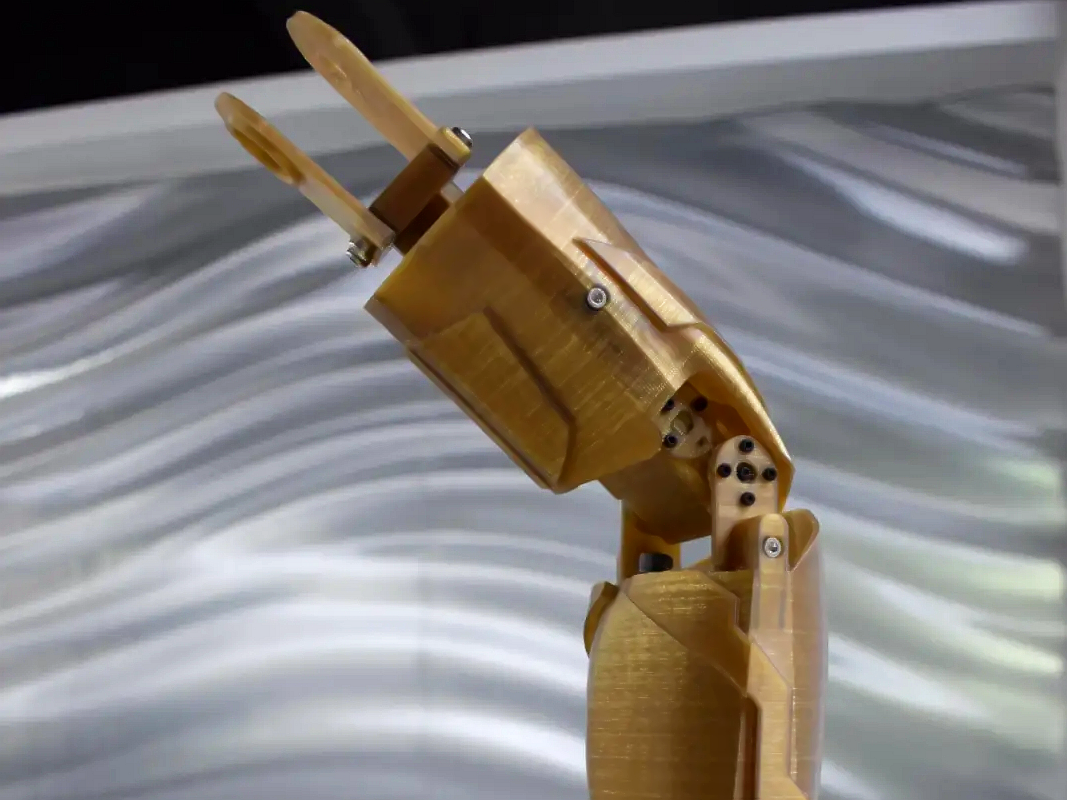

Custom Robotics Parts Prototyping

Robotics Components Online 3D Printing Service

Our online 3D printing service offers precision, durability, and speed. From metals to plastics, create tailored robotic components for any application. Unmatched quality, fast turnaround, and innovative materials—designed to elevate your robotic solutions!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Less Waste, More Innovation!

- Faster Prototypes, Smarter Solutions!

3D Printing in Robotics Manufacturing

3D Printing in Robotics Manufacturing enhances innovation by enabling rapid prototyping, custom component production, and lightweight, high-strength structures. Using materials like metals, plastics, and composites, it creates intricate robotic parts, housings, and joints with precision. This technology accelerates development, reduces costs, and improves performance in industrial, medical, and consumer robotics applications.

Benefits of 3D Printing In Robotics

3D printing in robotics accelerates development by enabling rapid prototyping, customization, weight reduction, and cost efficiency. This technology empowers engineers to produce tailored, lightweight components, driving innovation and lowering barriers in advanced robotic research and production.

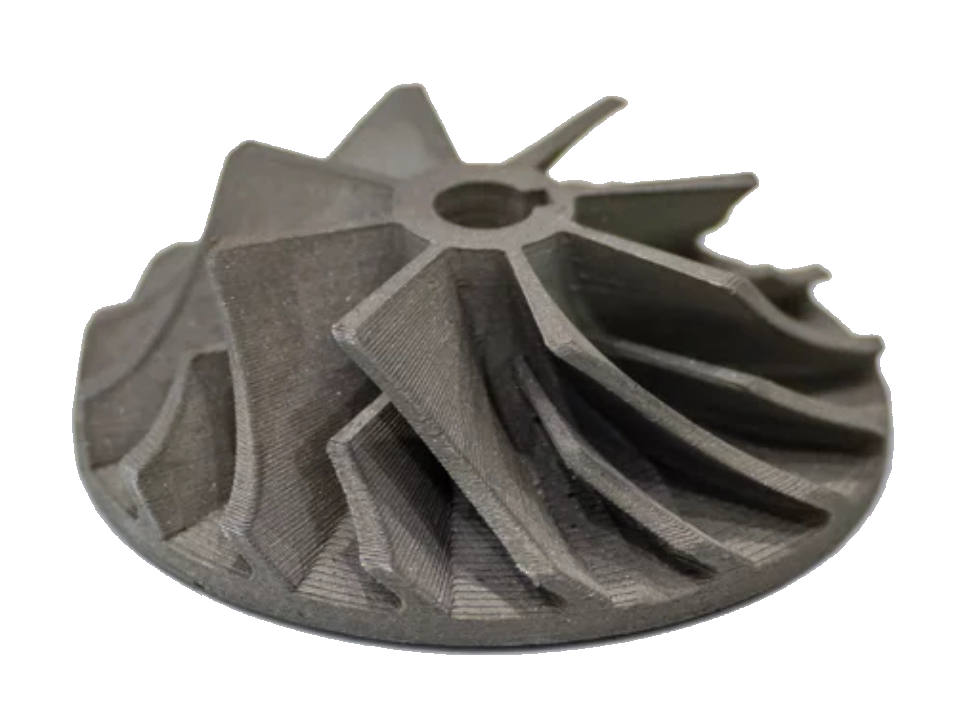

3D Printing Material Solution for Robotics

From durable metals to versatile plastics, our solutions deliver strength, efficiency, and innovation. Optimize performance with superalloys, titanium, ceramics, and more—tailored for robotic excellence. Revolutionize your creations with unmatched material quality and precision!

Post Process for 3D Printed Robotics Components

Post-processing techniques like CNC Machining, EDM, Heat Treatment, HIP, TBC, and Surface Treatment refine and strengthen your robotic parts, ensuring improved precision, durability, and performance for critical applications in robotics.

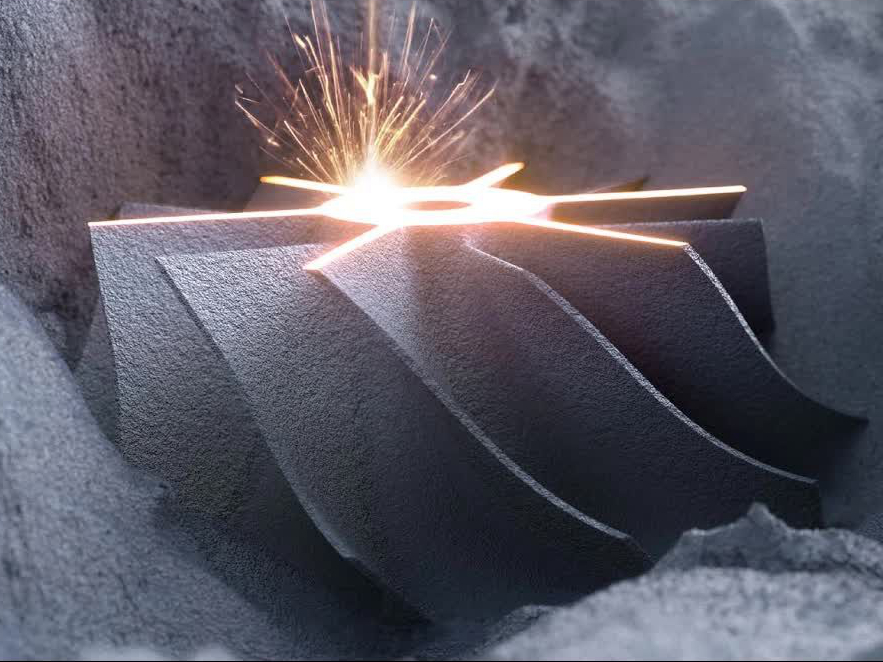

3D Printing Process Solution

Explore a range of advanced 3D printing processes like Material Extrusion, Vat Photopolymerization, Powder Bed Fusion, and more. Perfect for precision, durability, and innovation in your manufacturing, prototyping, and design projects. Transform your ideas into reality!

Case Study

Let's Start A New Project Today