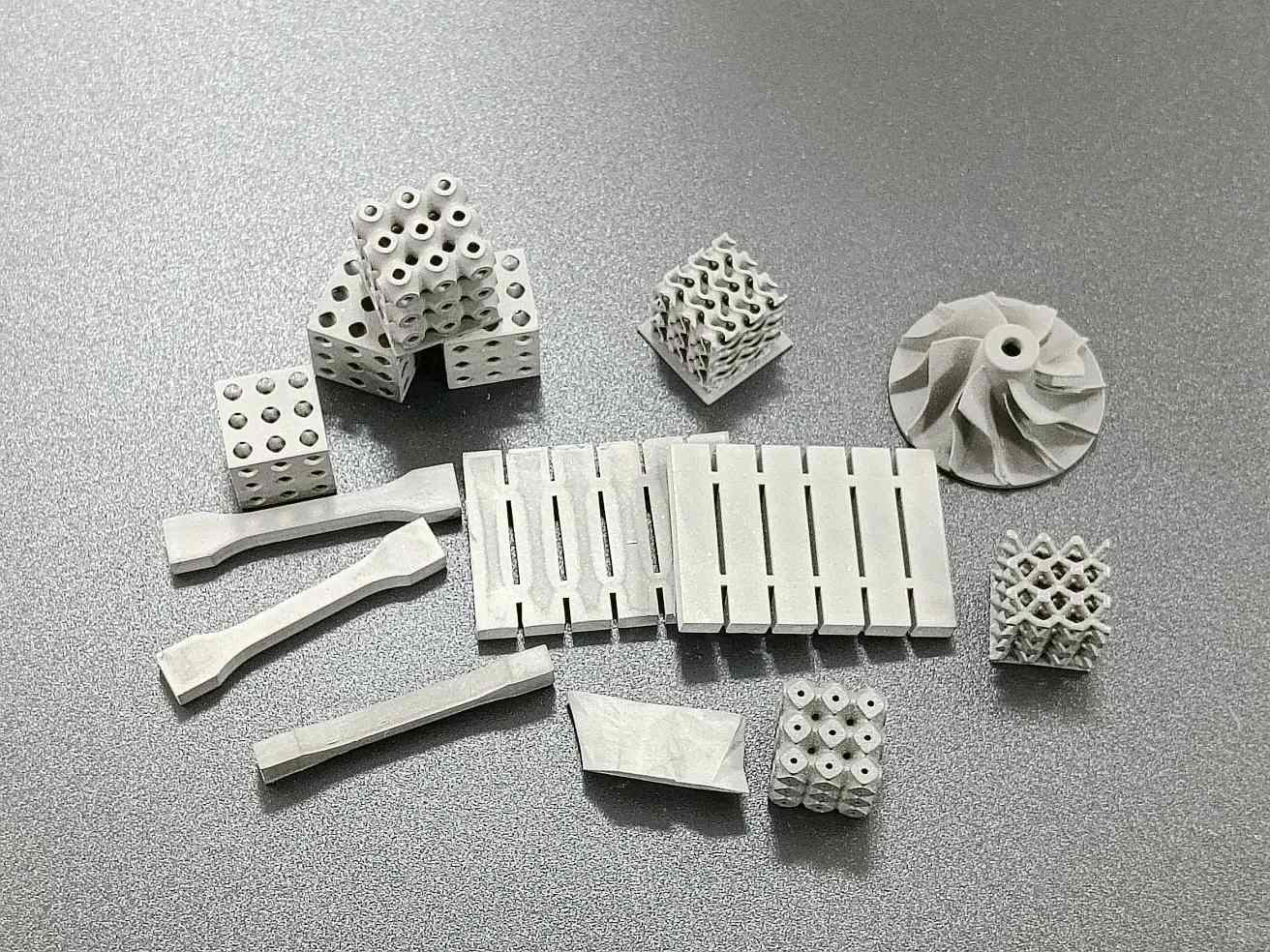

3D Printing Prototyping

Online 3D Printing Rapid Prototyping Service

Experience rapid prototyping at its best. Precise, affordable, and fast solutions tailored to your needs. Upload your design, select materials, and watch innovation come to life—delivered straight to your door!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Less Waste, More Innovation!

- Faster Prototypes, Smarter Solutions!

3D Printing In Rapid Prototyping

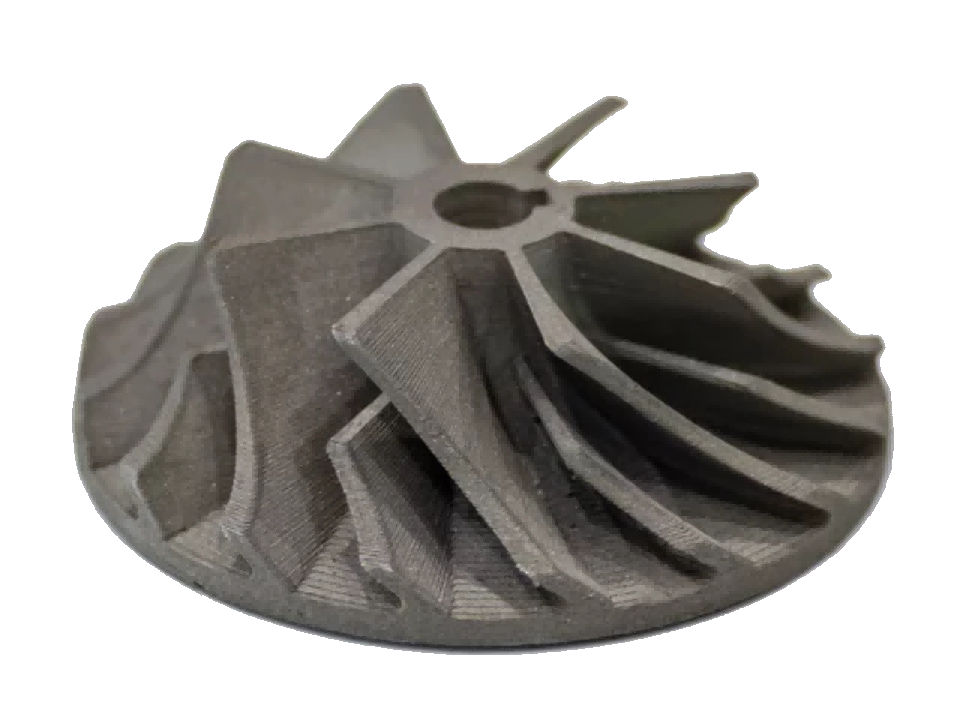

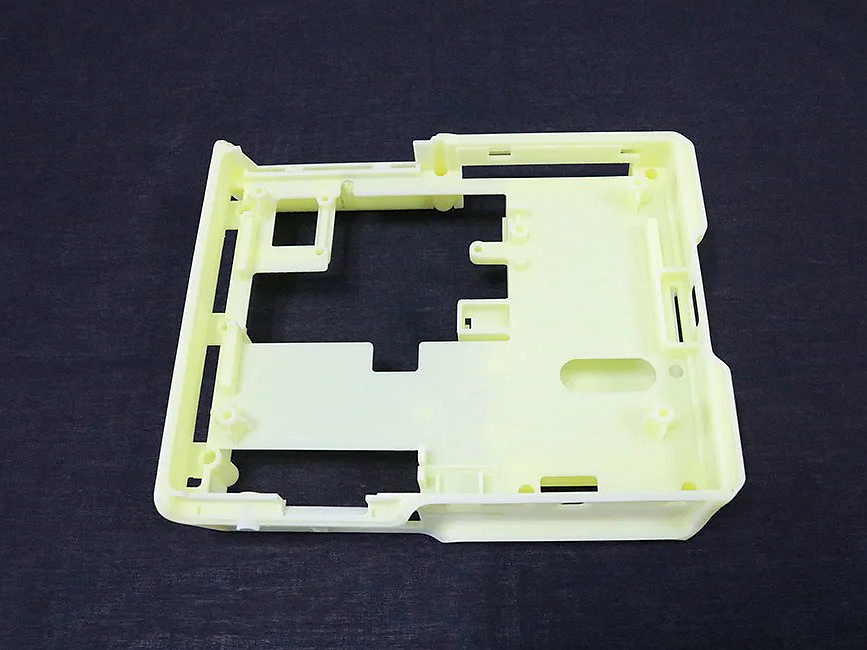

3D Printing Rapid Prototyping Service enables fast, cost-effective development of product designs with high precision. Using advanced 3D printing technologies, it produces functional prototypes in various materials, including metals, plastics, and resins. Ideal for testing, validation, and design iteration, it accelerates innovation across industries like aerospace, automotive, and healthcare.

Benefits of 3D Printing In Rapid Prototyping

Benefits of 3D Printing in Rapid Prototyping include faster design iterations, reduced development costs, and enhanced design flexibility. It enables quick testing of complex geometries using various materials, from plastics to metals. This technology accelerates product development, minimizes waste, and improves efficiency across industries like aerospace, automotive, healthcare, and consumer electronics.

Material Solution for Rapid Prototyping

From superalloys to resins, we offer advanced 3D printing materials tailored for rapid prototyping. Achieve precision, durability, and speed in every design iteration. Unleash innovation with materials that meet your toughest challenges!

Post Process for 3D Printed Prototypes

Achieve precision, durability, and superior performance with advanced post-processing techniques. From CNC Machining to Thermal Barrier Coatings, our services refine your prototypes, ensuring they meet the highest standards for functionality, aesthetics, and strength.

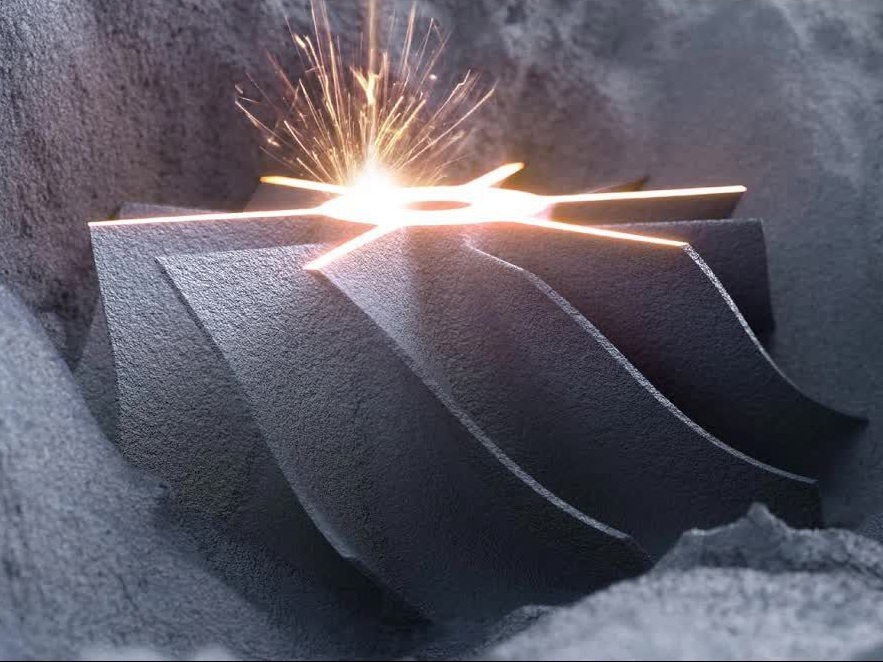

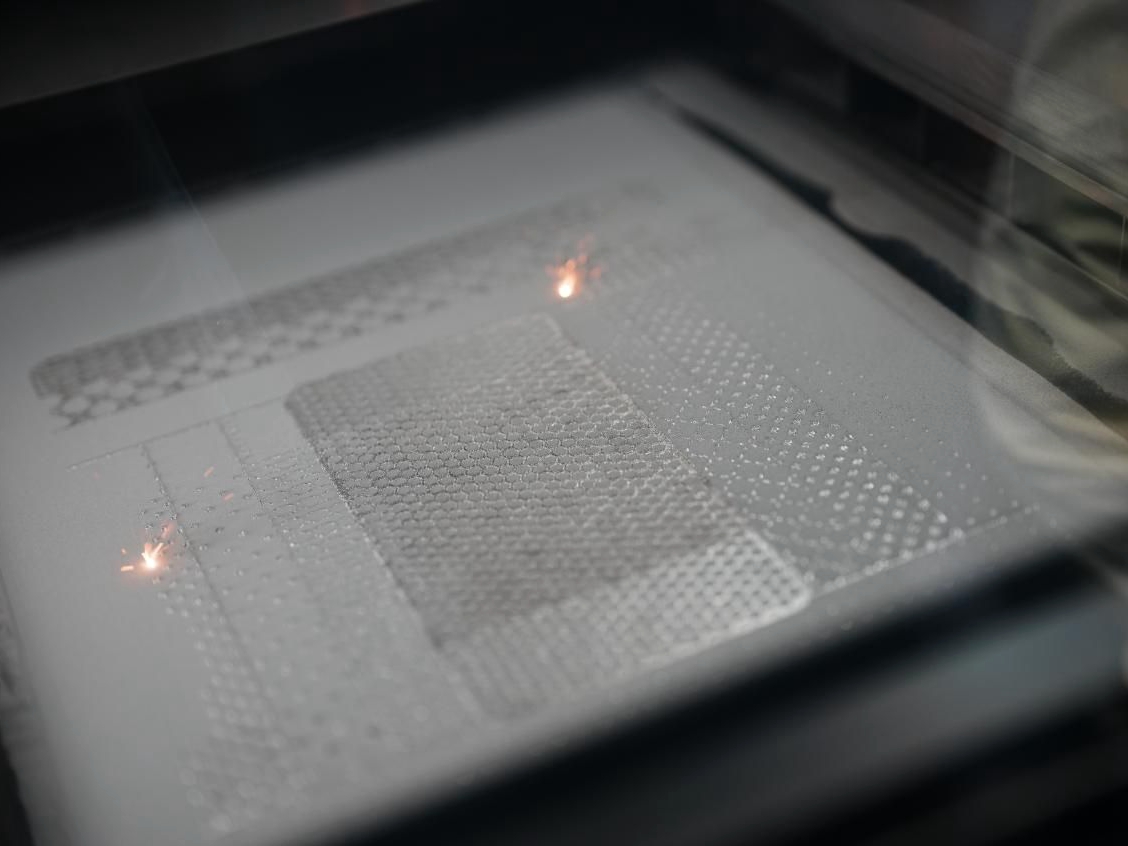

3D Printing Process Solution

Explore a range of advanced 3D printing processes like Material Extrusion, Vat Photopolymerization, Powder Bed Fusion, and more. Perfect for precision, durability, and innovation in your manufacturing, prototyping, and design projects. Transform your ideas into reality!

Case Study

Let's Start A New Project Today