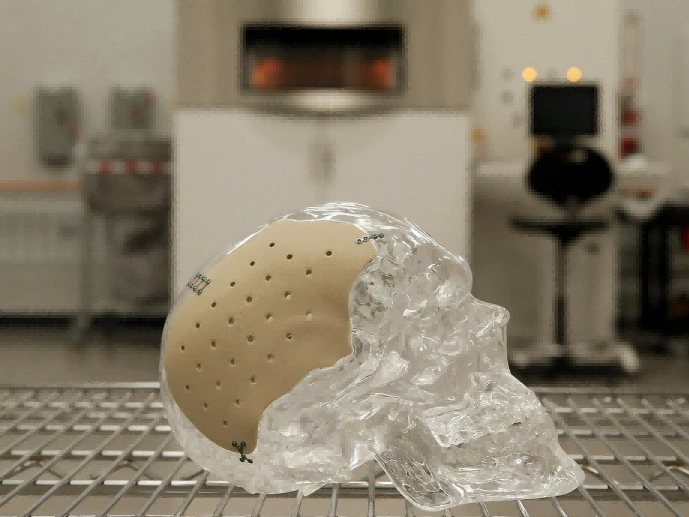

Medical and Healthcare Parts Prototyping

Medical and Healthcare Parts 3D Printing Service

Transform healthcare with our premium 3D printing services! From prosthetics to implants, we deliver precision, customization, and unmatched quality. Using advanced materials, we bring your designs to life, revolutionizing patient care. Partner with us for medical innovation today!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Less Waste, More Innovation!

- Faster Prototypes, Smarter Solutions!

3D Printing in Medical and Healthcare

3D Printing in Medical and Healthcare enables customized, high-precision solutions for patient care. It is used for prosthetics, implants, dental restorations, surgical models, and bioprinting. Utilizing biocompatible materials, metals, and resins, it enhances treatment outcomes, reduces costs, and accelerates medical innovation, making personalized healthcare more accessible and efficient.

Benefits of 3D Printing In Medical and Healthcare

3D printing in medical and healthcare enhances patient care and drives innovation by enabling customized devices, complex tool fabrication, rapid prototyping, and bioprinting capabilities that revolutionize treatment, surgical interventions, and regenerative medicine.

Material Solution for Medical and Healthcare Parts 3D Printing

Revolutionize medical innovation with our advanced 3D printing materials! From biocompatible titanium to detailed resins, our solutions ensure precision, durability, and customization for implants, prosthetics, and surgical tools. Elevate healthcare with cutting-edge material excellence. Explore possibilities today!

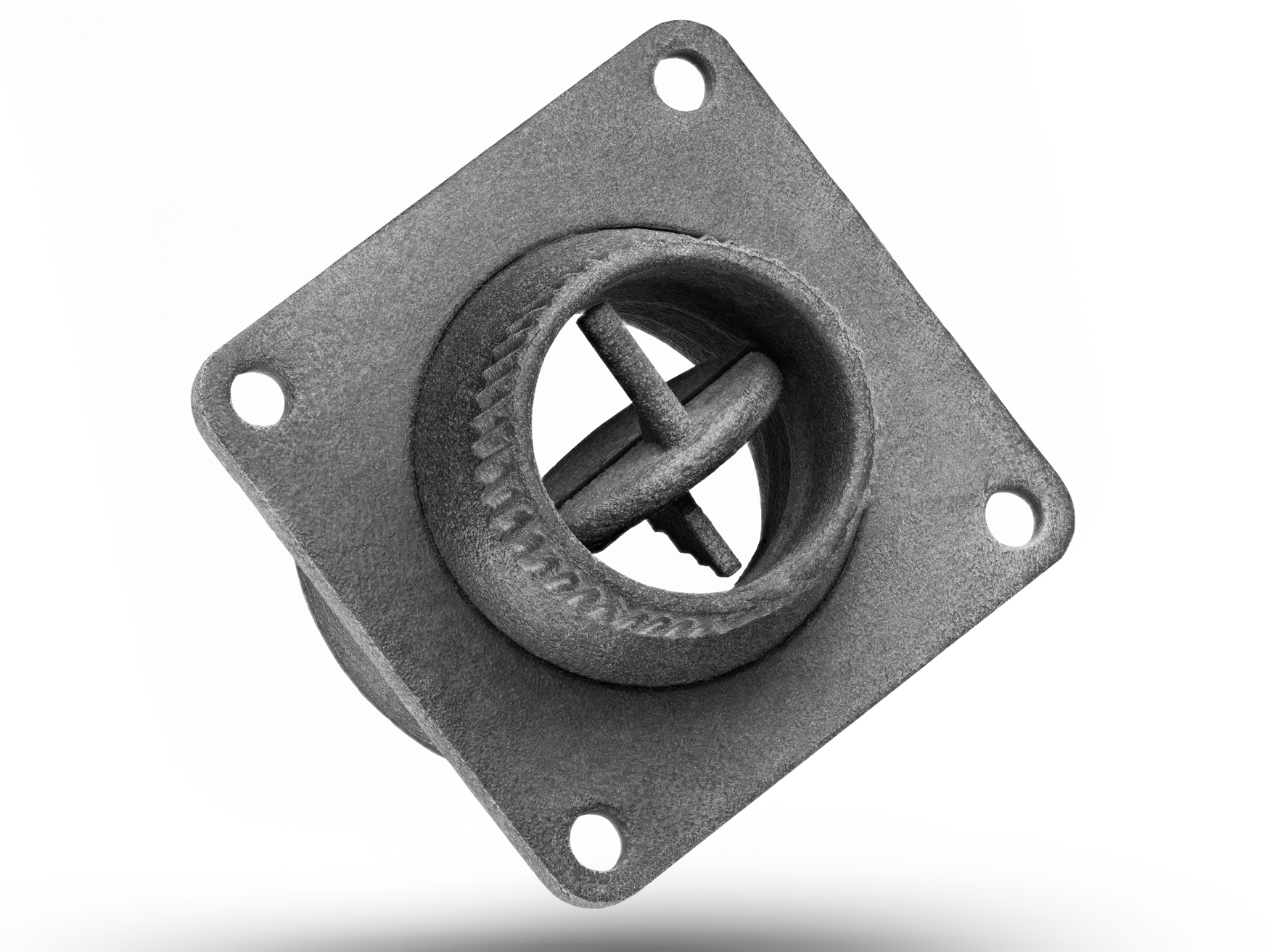

Post Process for 3D Printed Medical and Healthcare Parts

Enhance the performance and precision of 3D printed medical and healthcare parts with advanced post-processing techniques. From CNC machining to thermal barrier coatings, these processes ensure improved durability, strength, biocompatibility, and functionality for critical medical applications and implants.

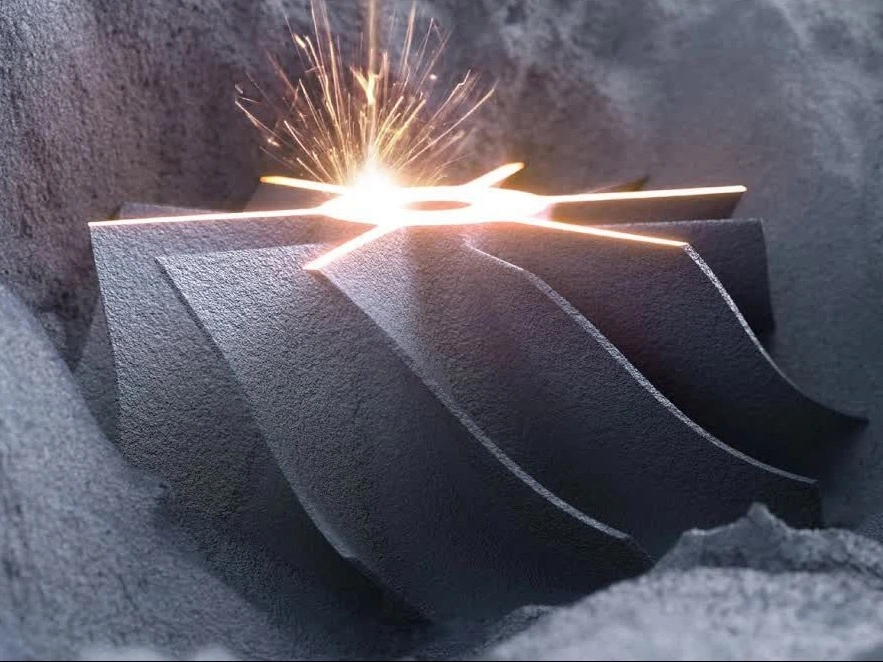

3D Printing Process Solution

Explore a range of advanced 3D printing processes like Material Extrusion, Vat Photopolymerization, Powder Bed Fusion, and more. Perfect for precision, durability, and innovation in your manufacturing, prototyping, and design projects. Transform your ideas into reality!

Case Study

Let's Start A New Project Today

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 3dp Precision Works Ltd.All Rights Reserved.