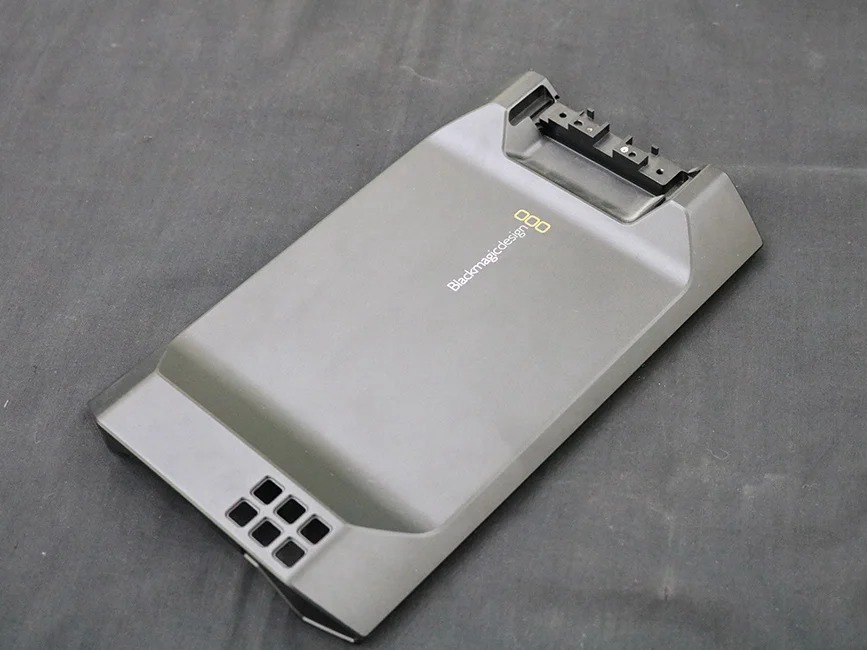

Manufacturing and Tooling Prototyping

Online Manufacturing and Tooling 3D Printing Service

Streamline production with our Online Manufacturing and Tooling 3D Printing Service. Precision-engineered parts, fast turnaround, and diverse materials ensure reliable, cost-effective solutions for every project. Simplify your workflow and achieve excellence with cutting-edge 3D printing technology. Get started today!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Less Waste, More Innovation!

- Faster Prototypes, Smarter Solutions!

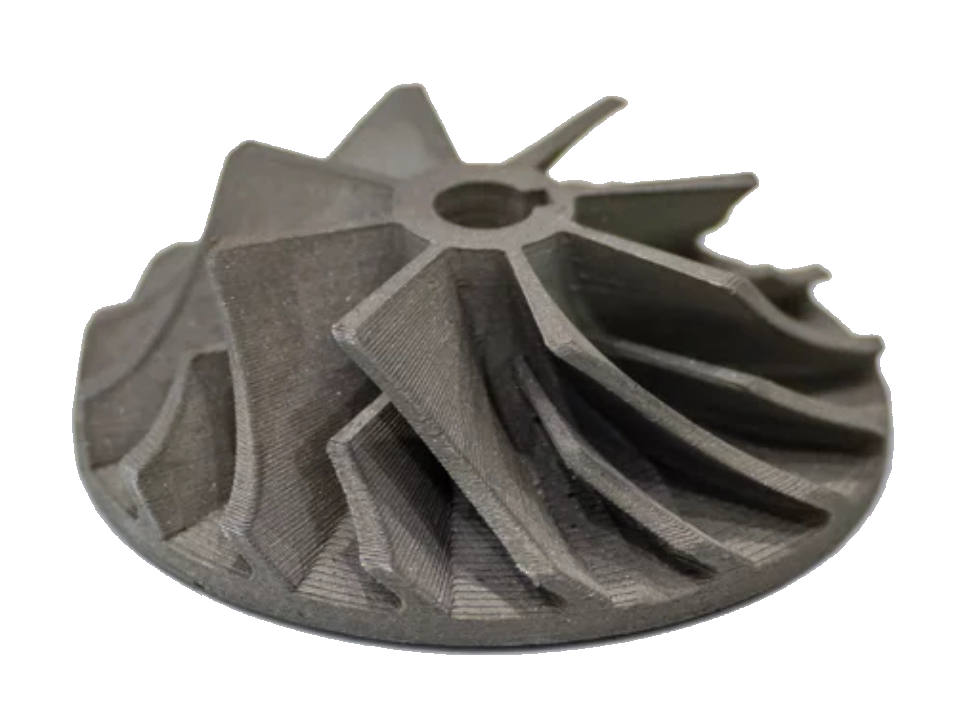

3D Printing in Manufacturing and Tooling

3D Printing in Manufacturing and Tooling enhances production efficiency by creating complex, high-precision parts and custom tools with reduced lead times. It enables rapid mold production, jigs, and fixtures using durable materials like metals and composites. This technology optimizes manufacturing processes, lowers costs, and supports on-demand, small-batch, or mass customization needs.

Benefits of 3D Printing In Manufacturing and Tooling

3D Printing in Manufacturing and Tooling offers significant advantages by enabling customization, managing complexity without extra cost, reducing lead times, and supporting on-demand production to streamline workflows and cut costs.

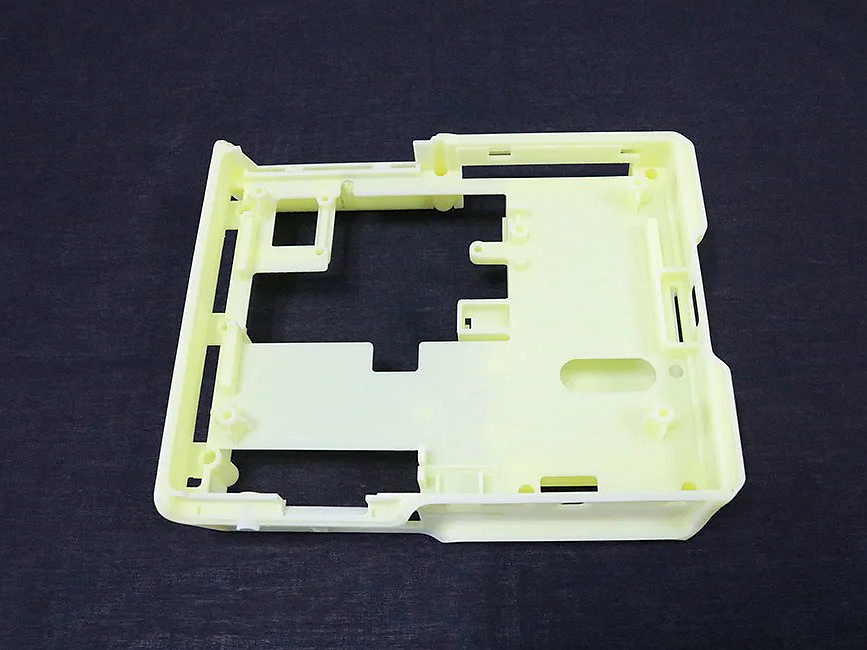

Material Solution for Manufacturing and Tooling

Transform your manufacturing and tooling with our advanced material solutions! From Superalloys to Plastics, we offer high-performance materials tailored for strength, precision, and innovation. Enhance productivity and durability in every application. Your tools deserve the best—choose us!

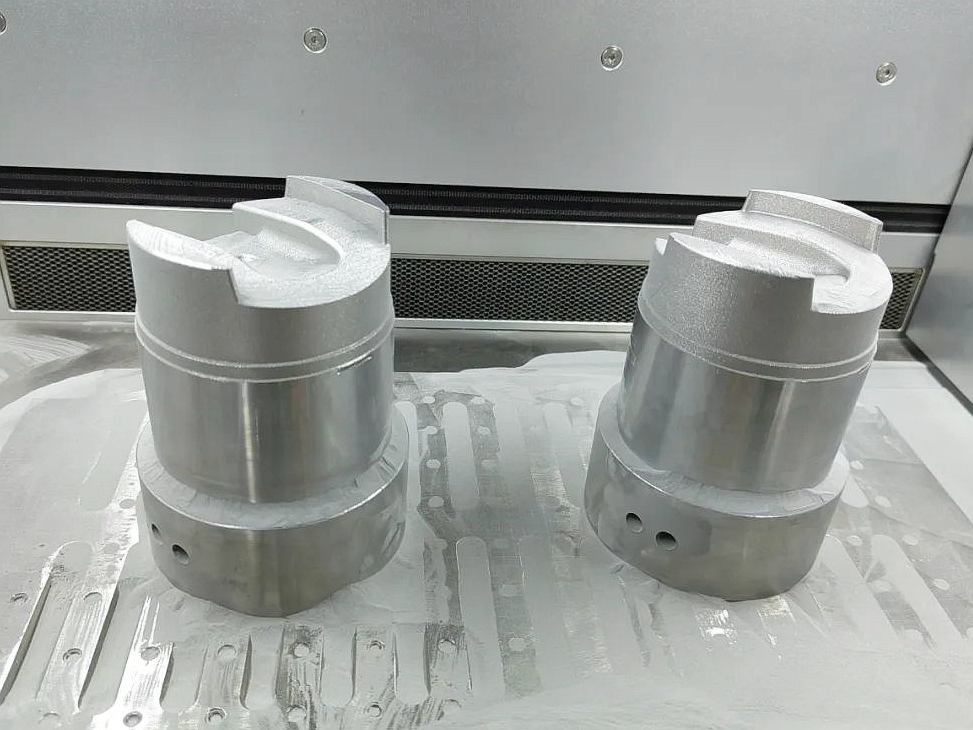

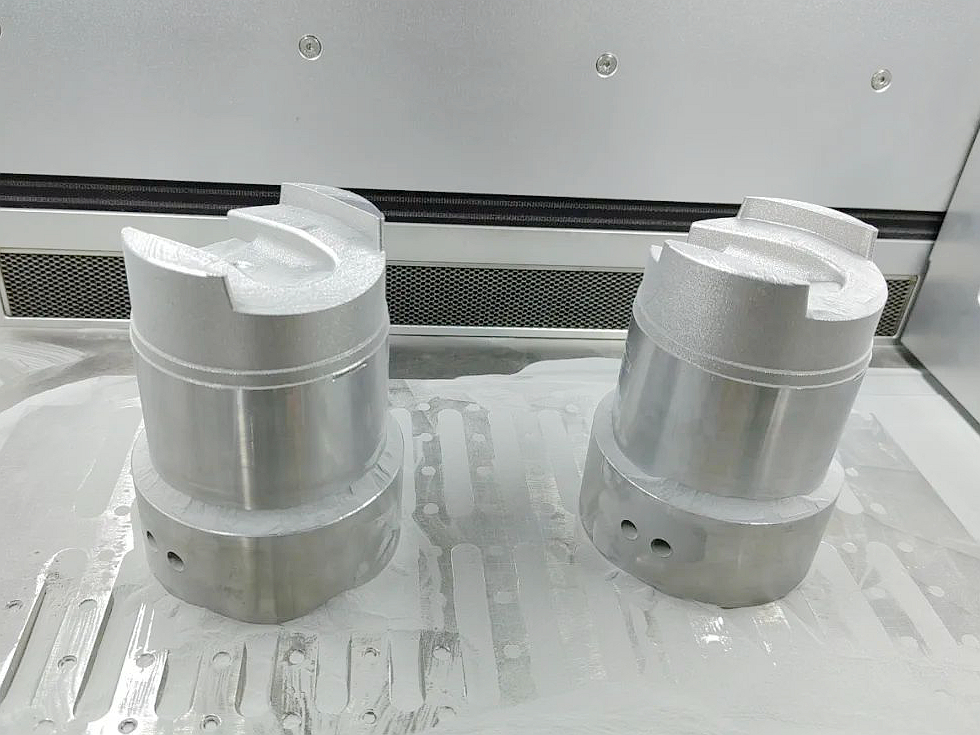

Post Process for 3D Printed Manufacturing and Tooling

Unlock the full potential of 3D printed manufacturing and tooling with our expert post-processing services. From CNC Machining and EDM to Heat Treatment, HIP, TBC, and Surface Treatment, we ensure superior quality, precision, and performance for every component.

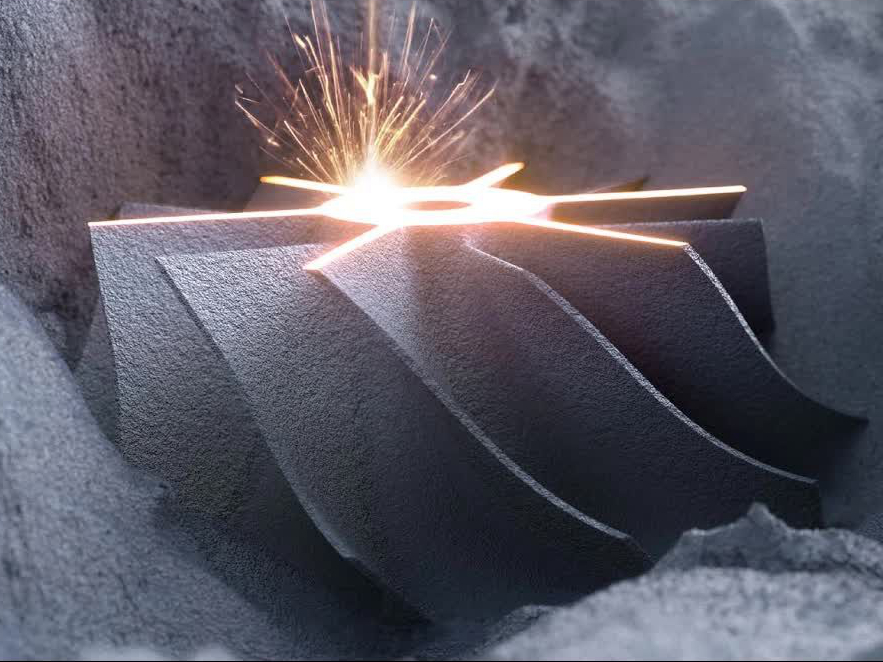

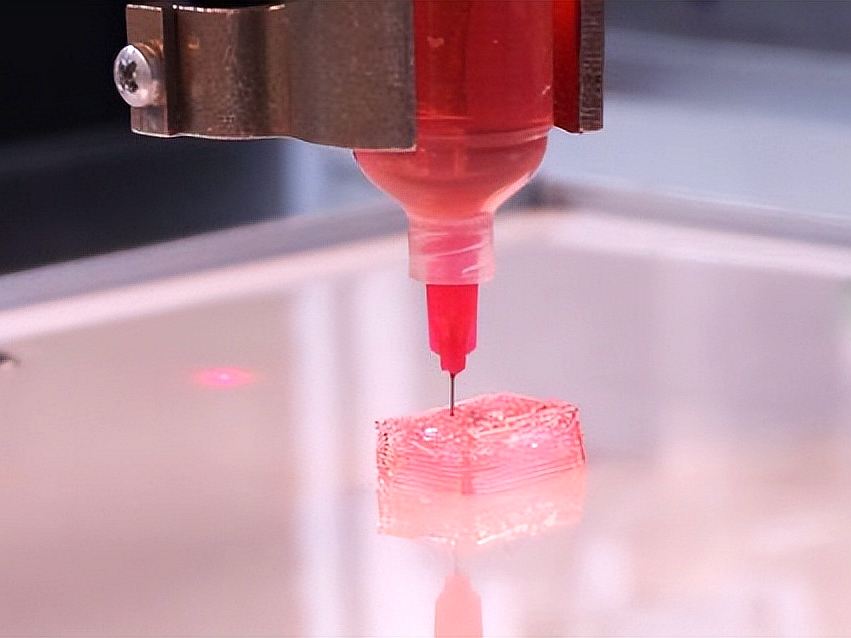

3D Printing Process Solution

Explore a range of advanced 3D printing processes like Material Extrusion, Vat Photopolymerization, Powder Bed Fusion, and more. Perfect for precision, durability, and innovation in your manufacturing, prototyping, and design projects. Transform your ideas into reality!

Case Study

Let's Start A New Project Today