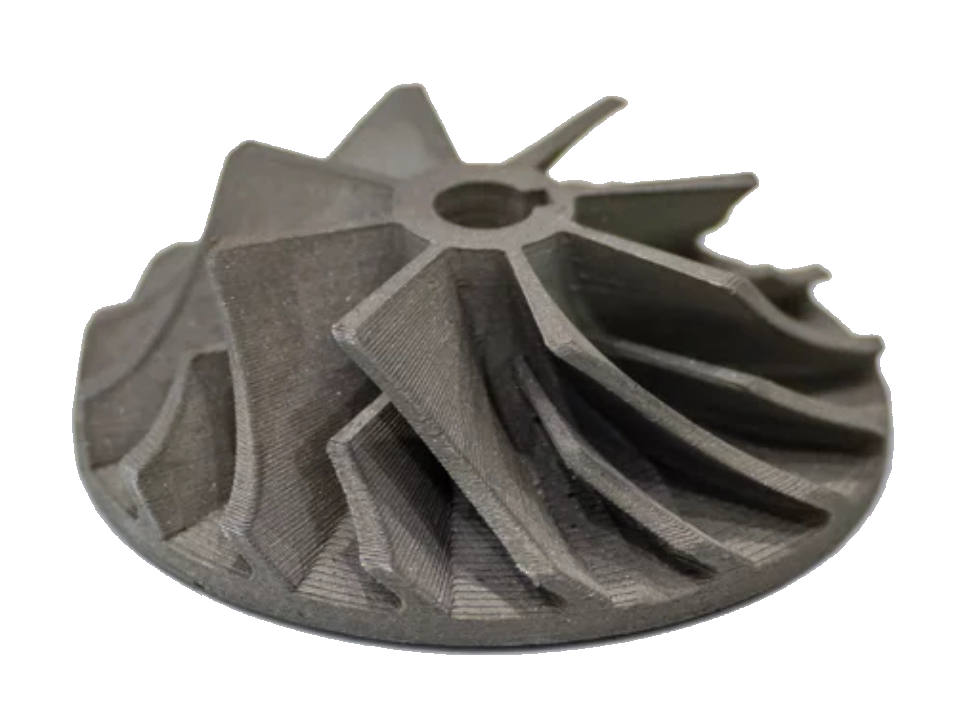

Fashion and Jewelry Parts Prototyping

Fashion and Jewelry Parts 3D Printing Service

Transform Your Ideas into Reality with Our Fashion and Jewelry 3D Printing Service! Experience precision, elegance, and durability using advanced materials. From intricate designs to bold accessories, we bring your creations to life. Unleash your creativity and shine in style today!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Less Waste, More Innovation!

- Faster Prototypes, Smarter Solutions!

3D Printing in Fashion and Jewelry Industry

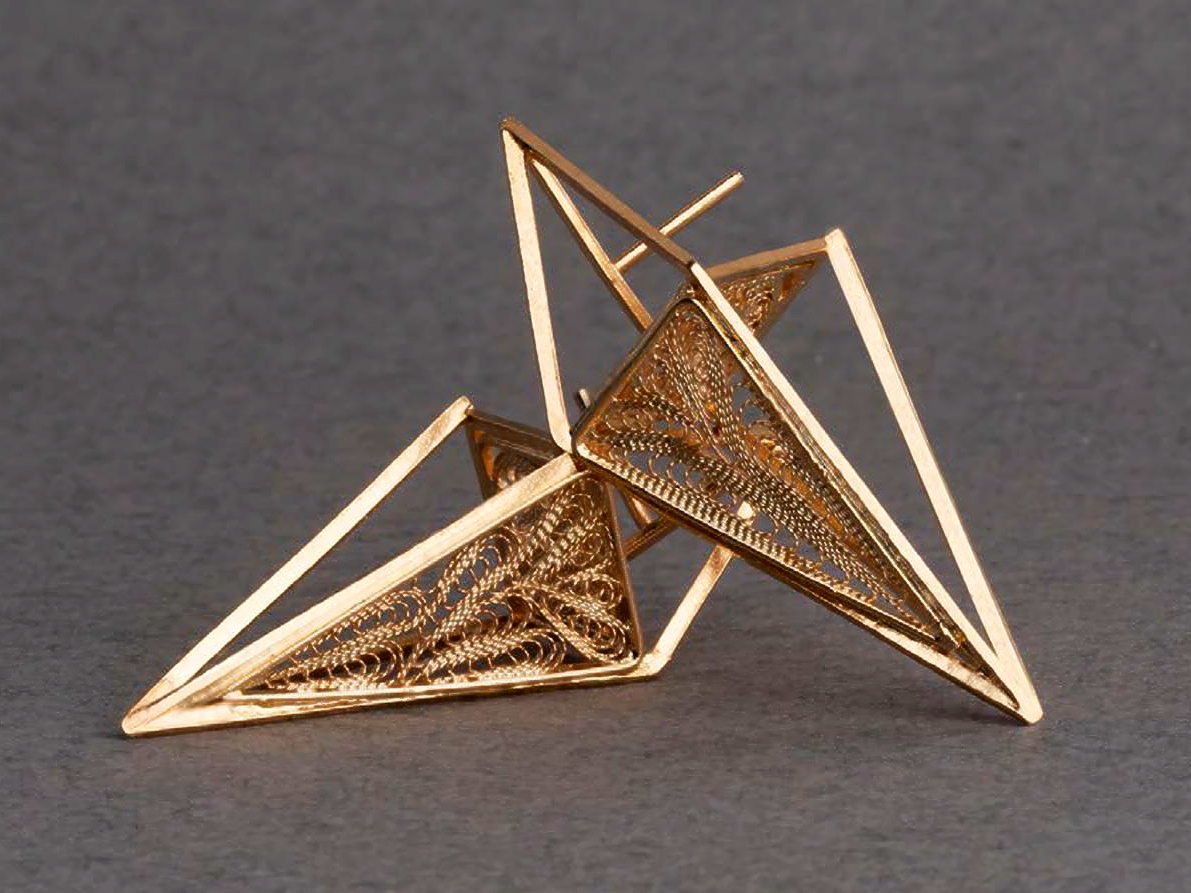

3D Printing in the Fashion and Jewelry Industry enables intricate, customized designs with precision and efficiency. It allows for rapid prototyping and production of unique accessories, footwear, and jewelry using materials like resins, metals, and flexible polymers. This technology enhances creativity, reduces material waste, and revolutionizes personalized, on-demand fashion manufacturing.

Benefits of 3D Printing In Fashion and Jewelry

3D printing transforms fashion and jewelry by enabling personalized designs, intricate detailing, rapid production, and sustainable practices. This innovative technology empowers designers to create unique, customized pieces while reducing waste and accelerating market responsiveness.

Material Solution for Fashion and Jewelry Parts 3D Printing

Revolutionize Your Fashion and Jewelry Designs with Premium 3D Printing Materials!

From lightweight titanium to intricate resins, our material solutions deliver precision, durability, and elegance. Perfect for creating unique, vibrant, and lasting accessories. Unleash your creativity today!

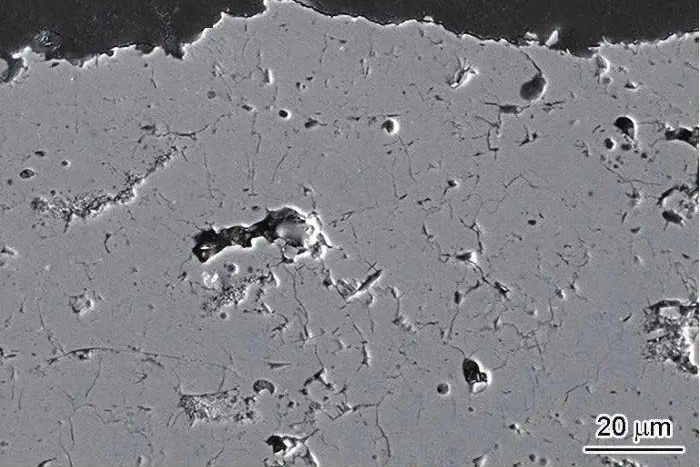

Post Process for 3D Printed Fashion and Jewelry Parts

Enhance Your 3D Printed Fashion and Jewelry Parts with Expert Post-Processing!

From precision CNC machining to advanced treatments like EDM, HIP, and thermal coatings, these post-processes refine your designs, improving durability, finish, and functionality for high-quality, long-lasting accessories.

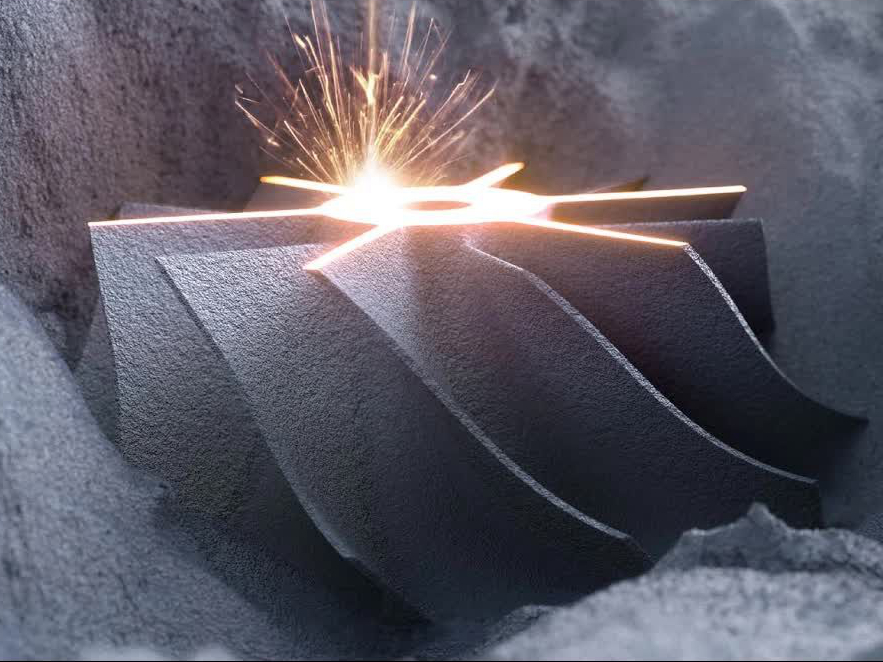

3D Printing Process Solution

Explore a range of advanced 3D printing processes like Material Extrusion, Vat Photopolymerization, Powder Bed Fusion, and more. Perfect for precision, durability, and innovation in your manufacturing, prototyping, and design projects. Transform your ideas into reality!

Case Study

Let's Start A New Project Today