Energy and Power Parts Prototyping

Energy and Power Parts 3D Printing Service

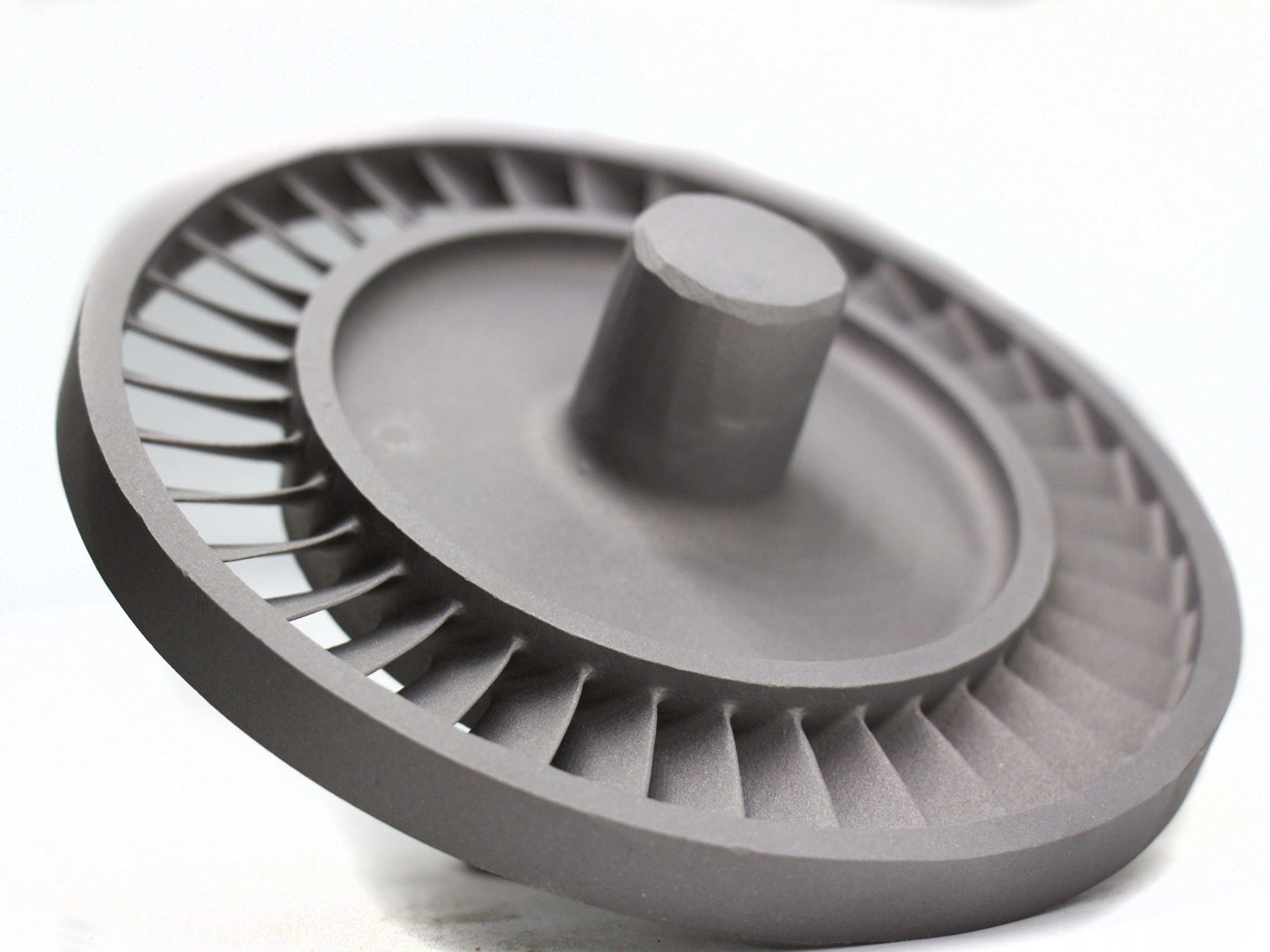

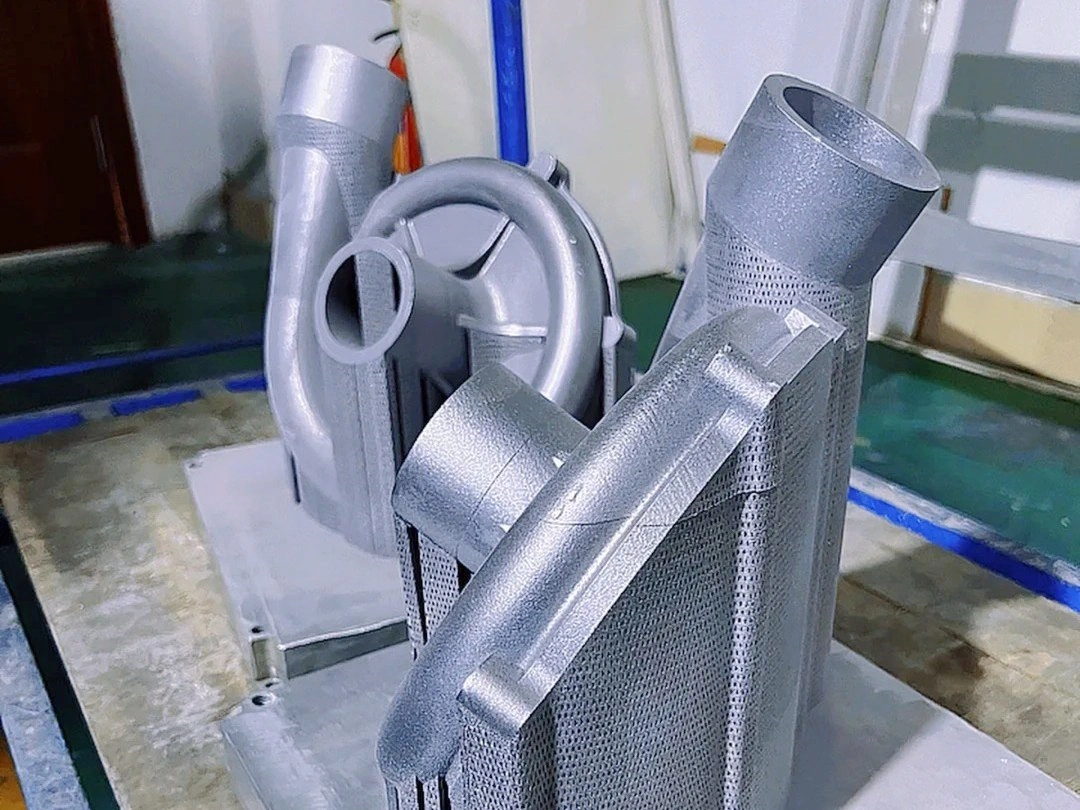

Unlock precision, strength, and efficiency for energy and power parts. From turbine blades to heat exchangers, our advanced 3D printing service delivers custom solutions using top-tier materials. Innovate smarter—partner with us today!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Less Waste, More Innovation!

- Faster Prototypes, Smarter Solutions!

3D Printing in Energy and Power Industry

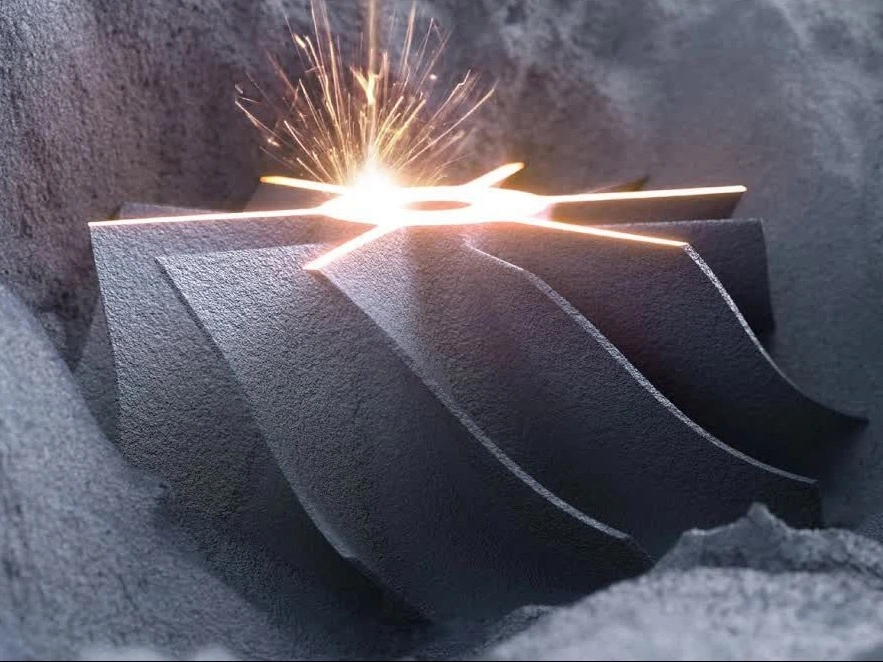

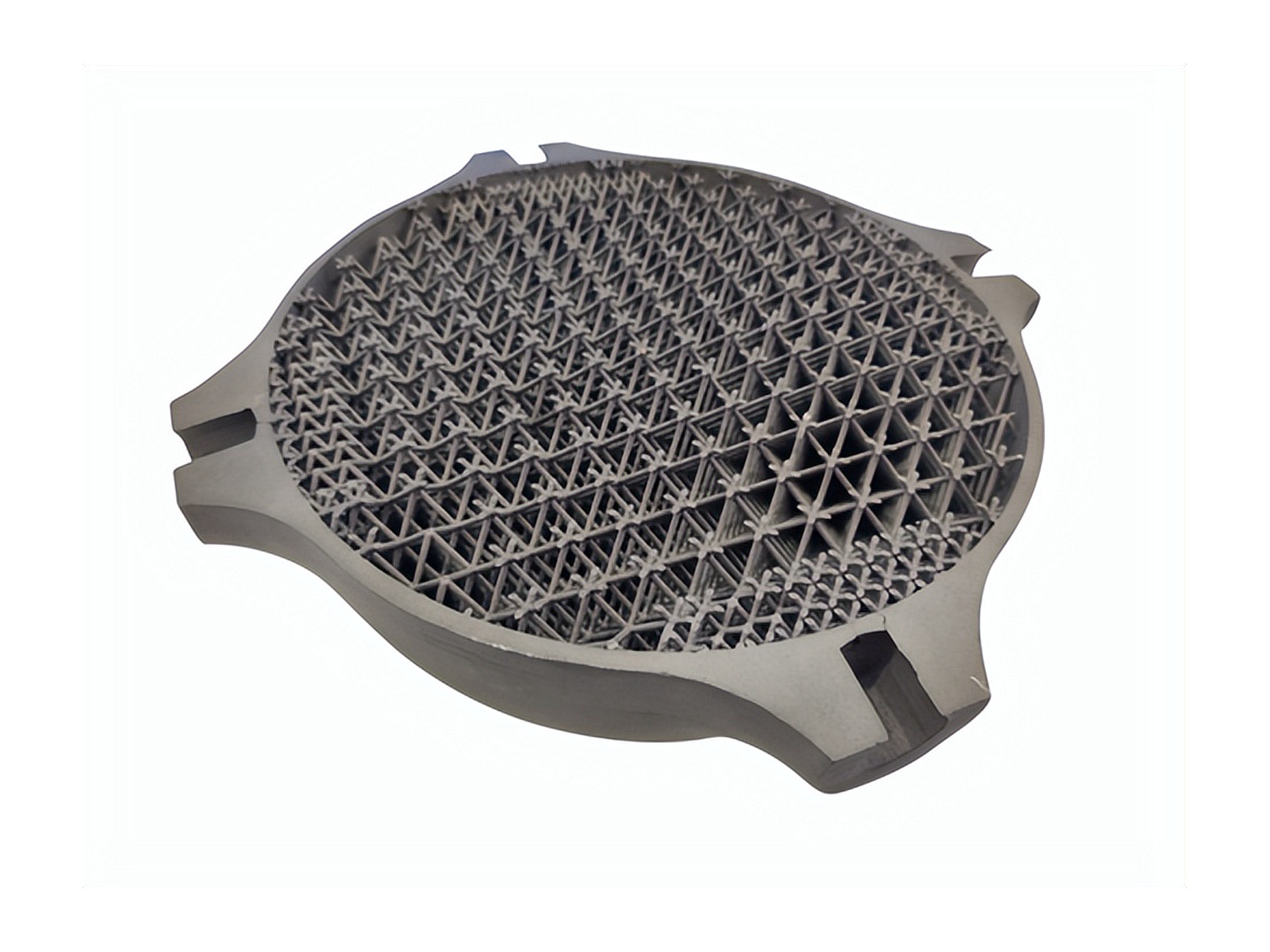

3D Printing in the Energy and Power Industry enhances efficiency by producing durable, high-performance components with complex geometries. It enables rapid manufacturing of turbine parts, heat exchangers, and custom tools using materials like superalloys and stainless steel. This technology reduces lead times, minimizes waste, and supports innovation in renewable and traditional energy sectors.

Benefits of 3D Printing In Energy and Power

3D printing in energy and power transforms component manufacturing by enabling customization, reducing lead times, lowering costs, and enhancing efficiency. This technology supports innovative energy solutions, from bespoke turbine blades to efficient heat exchangers, driving performance and sustainability in the energy sector.

Material Solution for Energy and Power Parts 3D Printing

From titanium alloys to ceramics, we provide top-tier materials like superalloys, stainless steel, and resins—engineered for durable, high-performance energy and power parts. Optimize strength, efficiency, and precision with our cutting-edge solutions!

Post Process for 3D Printed Energy and Power Parts

Post-processing techniques like CNC machining, EDM, heat treatment, HIP, TBC, and surface treatments refine and optimize your parts. Improve strength, precision, durability, and performance for demanding energy and power applications with these advanced methods.

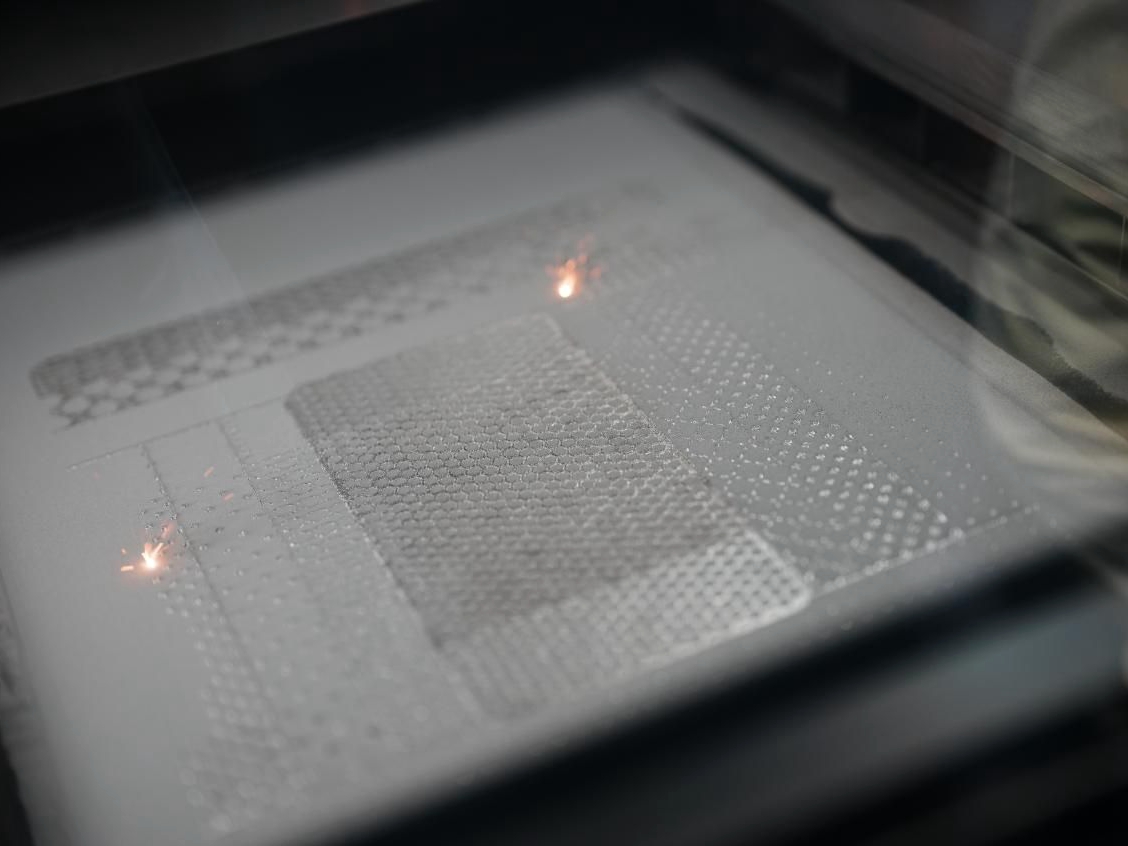

3D Printing Process Solution

Explore a range of advanced 3D printing processes like Material Extrusion, Vat Photopolymerization, Powder Bed Fusion, and more. Perfect for precision, durability, and innovation in your manufacturing, prototyping, and design projects. Transform your ideas into reality!

Case Study

Let's Start A New Project Today

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2025 3dp Precision Works Ltd.All Rights Reserved.