Education and Research Parts Prototyping

Education and Research Parts 3D Printing Service

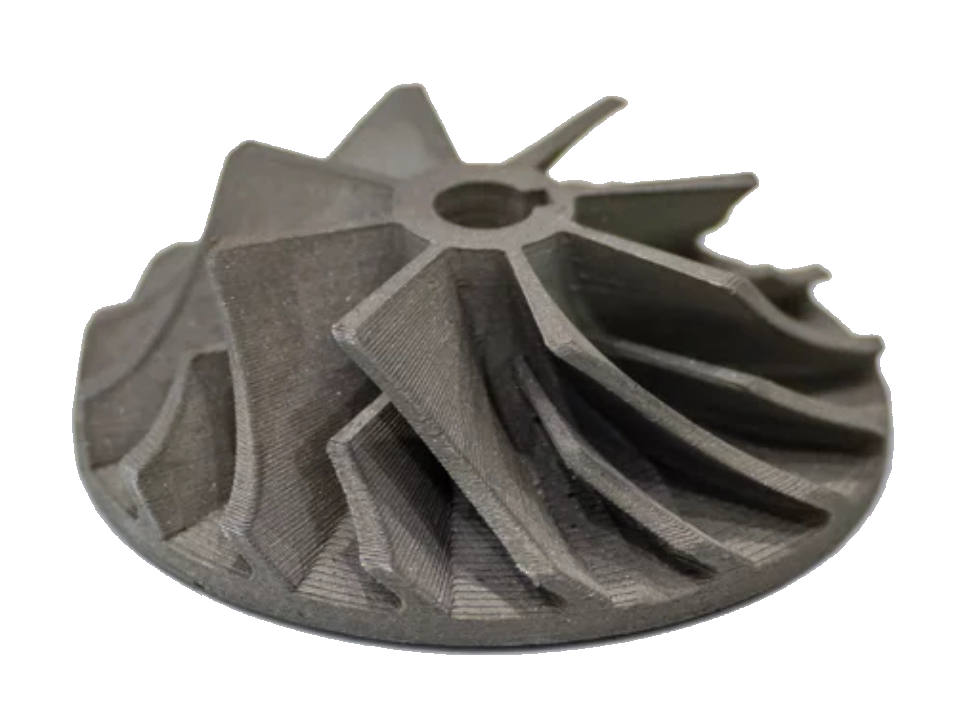

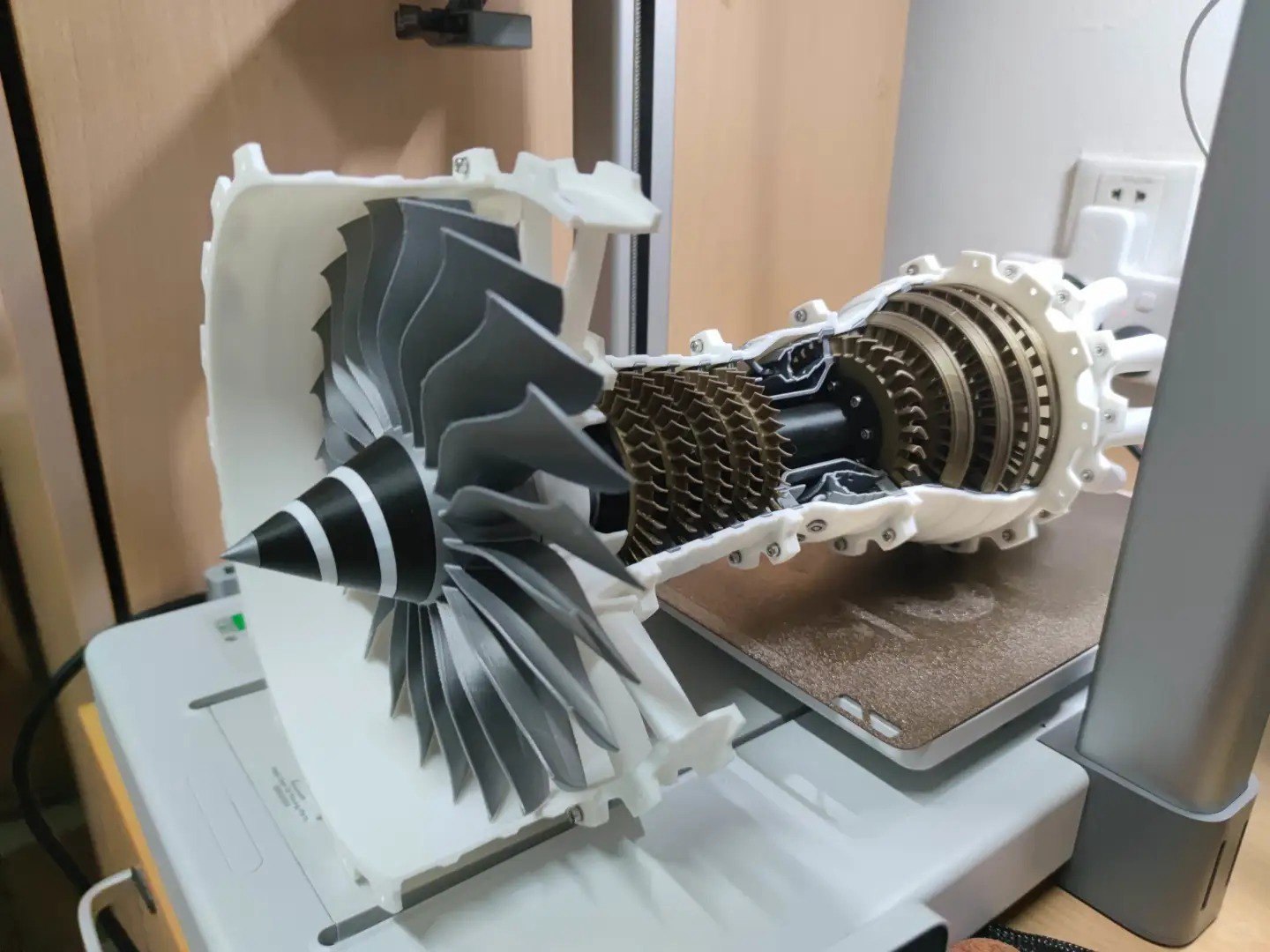

Create precise prototypes, durable parts, and innovative models for academic excellence. From engineering to materials science, we deliver customized solutions to enhance teaching, experiments, and groundbreaking discoveries. Partner with us for your 3D printing needs!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Less Waste, More Innovation!

- Faster Prototypes, Smarter Solutions!

3D Printing in Education and Research

3D Printing in Education and Research enhances learning and innovation by providing hands-on experience in design, engineering, and prototyping. It enables students and researchers to create complex models, scientific tools, and experimental components using diverse materials. This technology fosters creativity, accelerates discoveries, and supports advancements in various academic and scientific fields.

Benefits of 3D Printing In Education and Research

3D printing in education and research enriches learning through tangible models, fosters innovation, and provides cost-effective resources. It supports interdisciplinary applications and enhances hands-on understanding of complex concepts, empowering students and researchers alike.

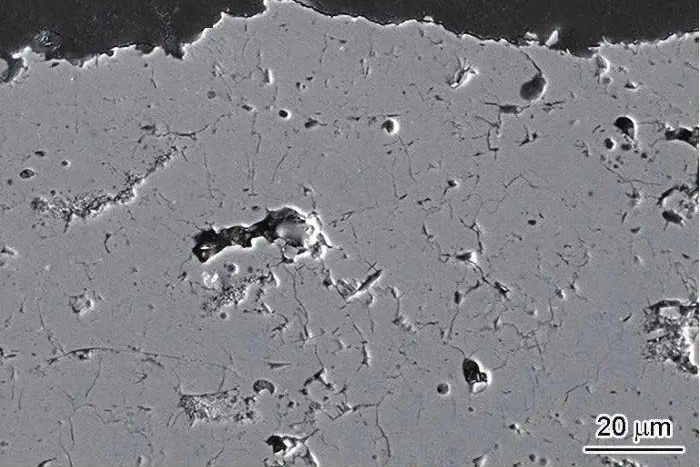

3D Printing Material Solution for Education and Research

From superalloys to resins, we offer versatile, high-quality solutions for prototyping, experiments, and teaching. Enhance innovation with durable, lightweight, and cost-effective materials tailored for academic excellence and breakthrough discoveries. Start creating today!

Post Process for 3D Printed Education and Research Parts

Post-processing techniques like CNC Machining, EDM, Heat Treatment, HIP, TBC, and Surface Treatment refine 3D printed parts, improving precision, durability, and performance for advanced educational experiments, prototyping, and research applications.

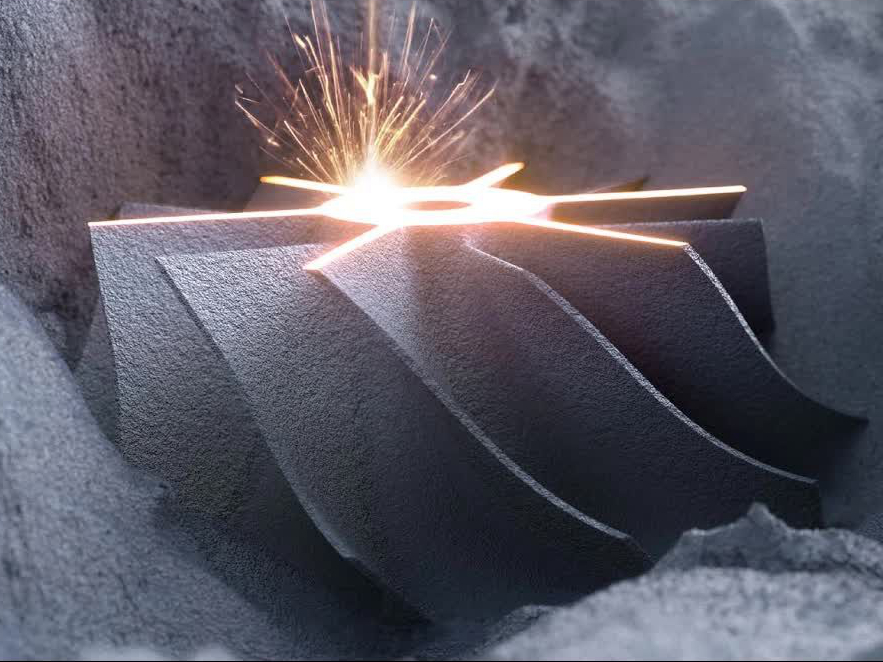

3D Printing Process Solution

Explore a range of advanced 3D printing processes like Material Extrusion, Vat Photopolymerization, Powder Bed Fusion, and more. Perfect for precision, durability, and innovation in your manufacturing, prototyping, and design projects. Transform your ideas into reality!

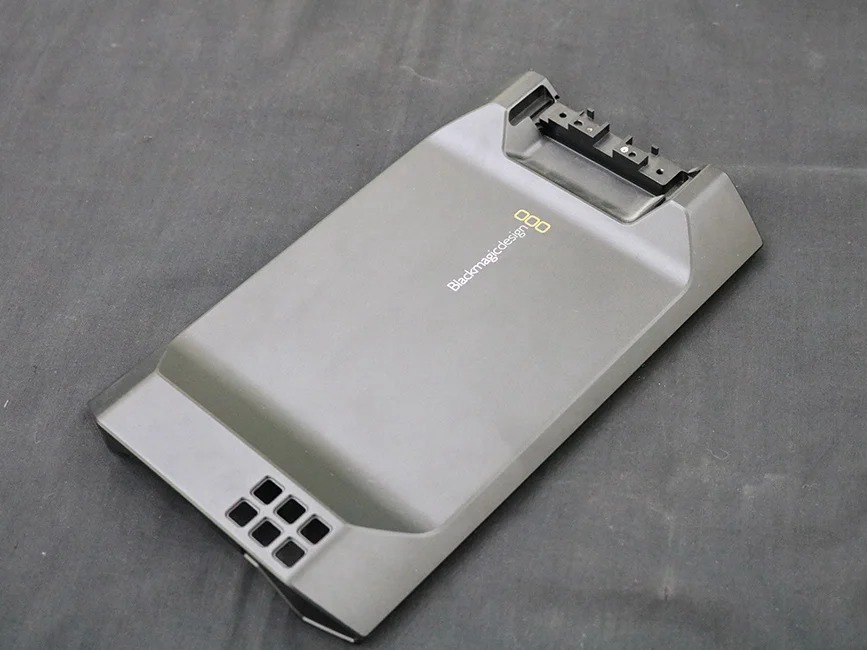

Case Study

Let's Start A New Project Today