Consumer Electronics Parts Prototyping

Consumer Electronics Parts 3D Printing Service

Transform your ideas into reality with our Consumer Electronics Parts 3D Printing Service! Precision, durability, and customization come standard. From prototypes to production, we deliver cutting-edge solutions tailored to your electronic design needs. Start innovating today!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Less Waste, More Innovation!

- Faster Prototypes, Smarter Solutions!

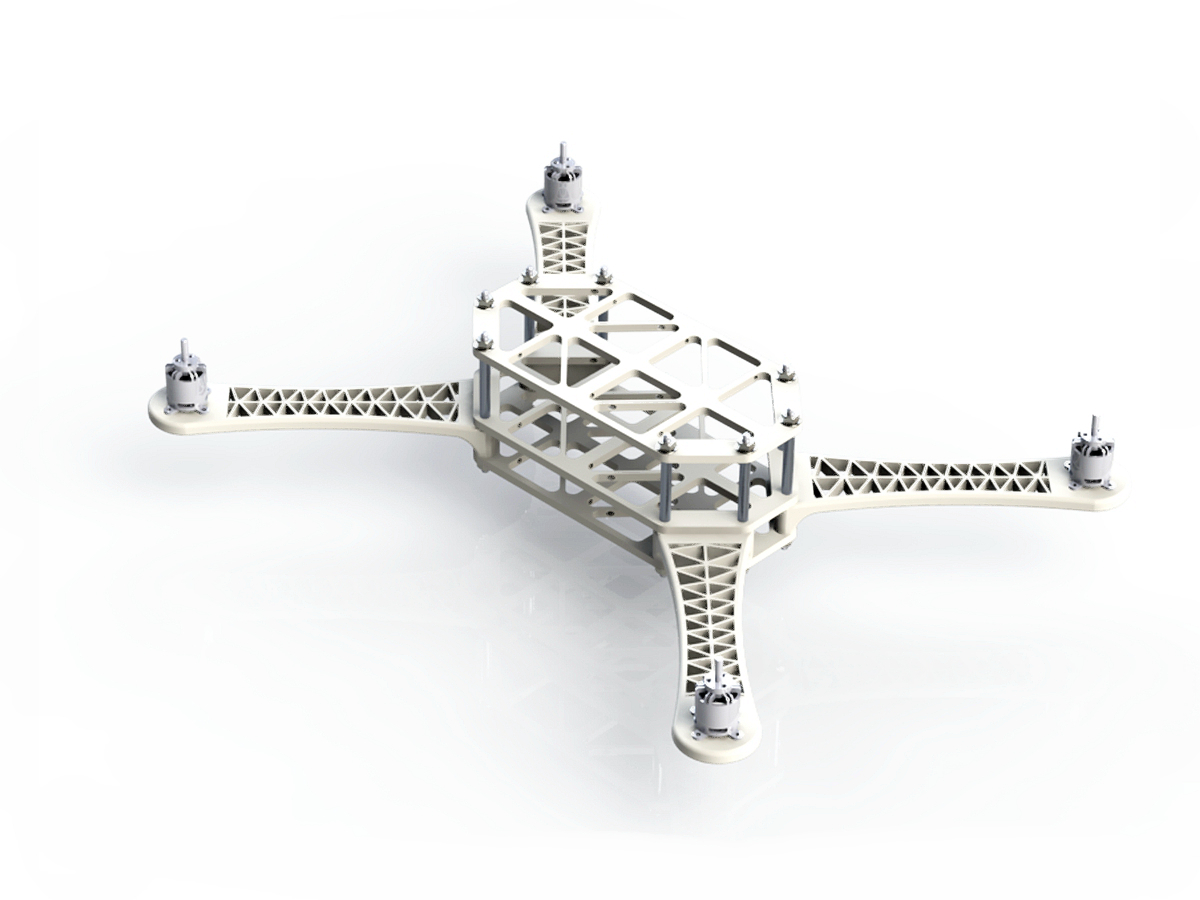

3D Printing in Consumer Electronics

3D Printing in Consumer Electronics accelerates product development, enabling rapid prototyping and customized manufacturing. It produces intricate components, housings, and circuit boards using materials like plastics, resins, and conductive filaments. This technology enhances design flexibility, reduces waste, and supports innovation in wearables, smartphones, and smart devices, driving the future of electronic product development.

Benefits of 3D Printing In Consumer Electronics

3D printing in consumer electronics enables rapid prototyping, high customization, and production of complex geometries for cost-effective small batch manufacturing. This innovative technology accelerates design cycles and market entry, providing a competitive edge for new and personalized electronic devices.

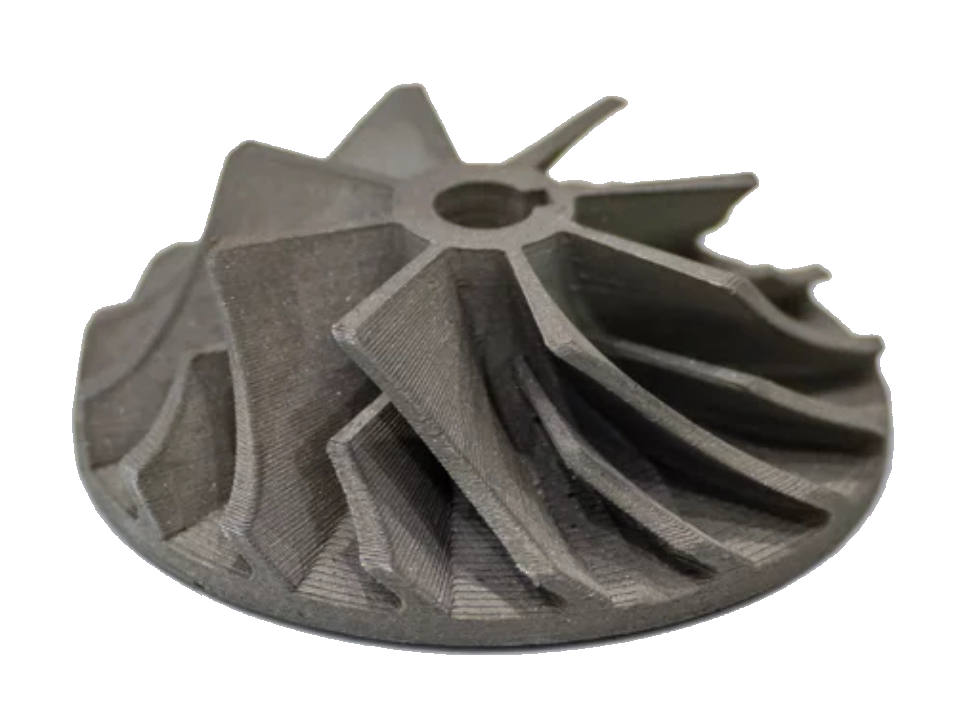

Material Solution for Consumer Electronics Parts 3D Printing

Revolutionize your consumer electronics with our advanced 3D printing material solutions! From durable metals to precision resins, achieve lightweight, heat-resistant, and customizable parts tailored for performance and design. Elevate innovation with materials engineered for cutting-edge consumer technology!

Post Process for 3D Printed Consumer Electronics Parts

Enhance the performance and durability of your 3D printed consumer electronics parts with advanced post-processing techniques. From precision CNC machining to heat treatments and specialized coatings, these processes optimize strength, surface quality, and thermal resistance for superior electronic components.

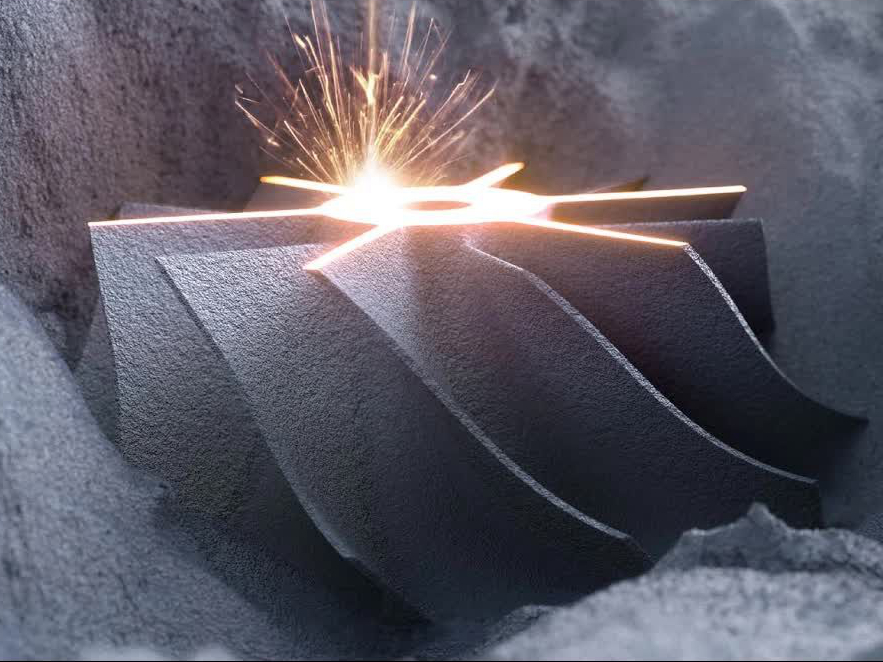

3D Printing Process Solution

Explore a range of advanced 3D printing processes like Material Extrusion, Vat Photopolymerization, Powder Bed Fusion, and more. Perfect for precision, durability, and innovation in your manufacturing, prototyping, and design projects. Transform your ideas into reality!

Case Study

Let's Start A New Project Today