Architecture and Construction Parts Prototyping

Custom Architecture Parts 3D Printing Service

Transform your construction projects with our Architecture and Construction 3D Printing Services! Delivering precision, durability, and innovation using premium materials like titanium, ceramics, and stainless steel. Build smarter, faster, and more efficiently. Elevate your designs to new heights today!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Less Waste, More Innovation!

- Faster Prototypes, Smarter Solutions!

3D Printing in Architecture and Construction

3D Printing in Architecture and Construction revolutionizes building design by enabling rapid, cost-effective production of complex structures. It allows for customized models, prefabricated components, and even full-scale buildings using concrete, composites, and sustainable materials. This technology enhances efficiency, reduces waste, and supports innovative, sustainable construction solutions for modern architectural projects.

Benefits of 3D Printing In Architecture and Construction

3D printing in architecture and construction unlocks creative freedom, cost efficiency, rapid assembly, and sustainable building practices. It enables intricate design realization, minimizes material waste, expedites construction timelines, and supports eco-friendly methods, revolutionizing modern building techniques.

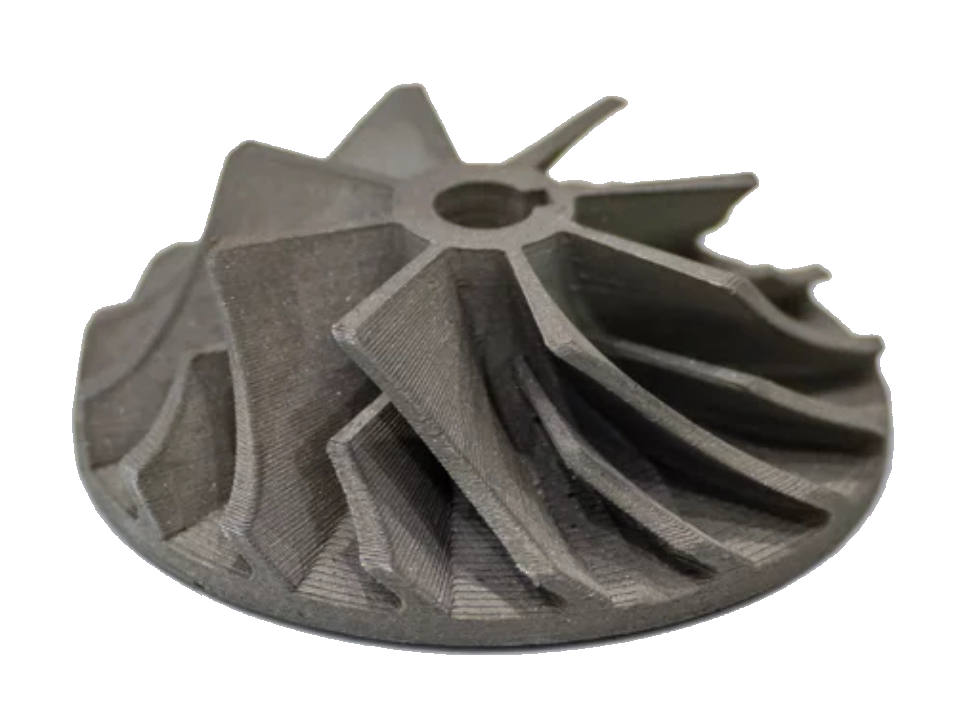

Material Solution for Architecture and Construction Parts 3D Printing

Revolutionize architecture with cutting-edge materials for 3D printing! From titanium to ceramics, we offer durable, lightweight, and versatile solutions for every construction need. Build smarter, stronger, and more efficiently with our premium material solutions. Elevate your projects today!

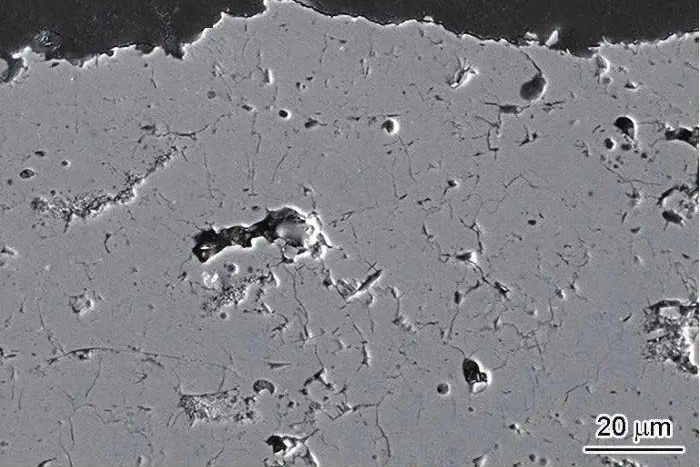

Post Process for 3D Printed Architecture Parts

Enhance the quality and durability of your 3D printed architecture parts with advanced post-processing techniques. From CNC Machining to Surface Treatment, explore methods like EDM, Heat Treatment, and HIP for improved precision, strength, and performance in every design.

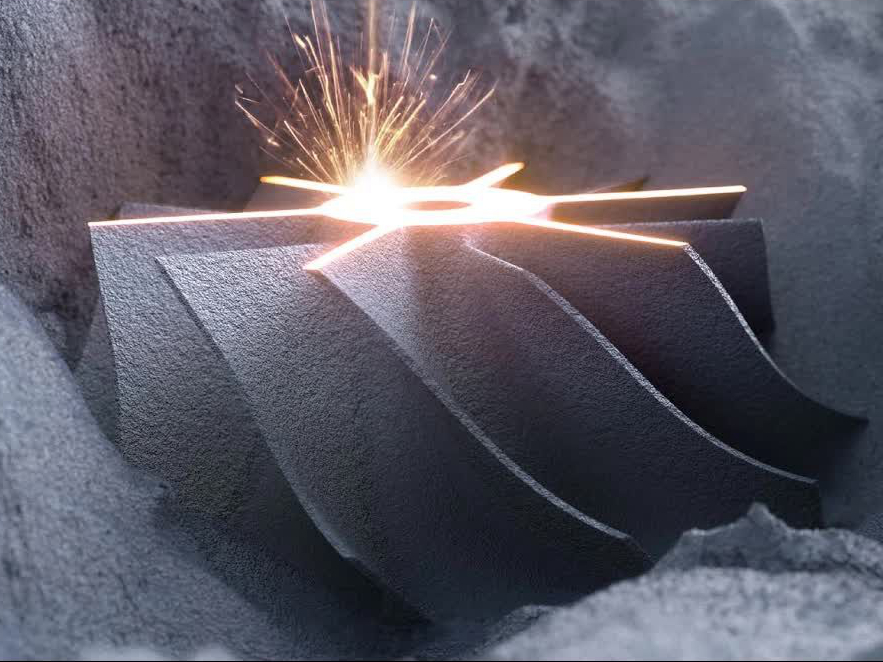

3D Printing Process Solution

Explore a range of advanced 3D printing processes like Material Extrusion, Vat Photopolymerization, Powder Bed Fusion, and more. Perfect for precision, durability, and innovation in your manufacturing, prototyping, and design projects. Transform your ideas into reality!

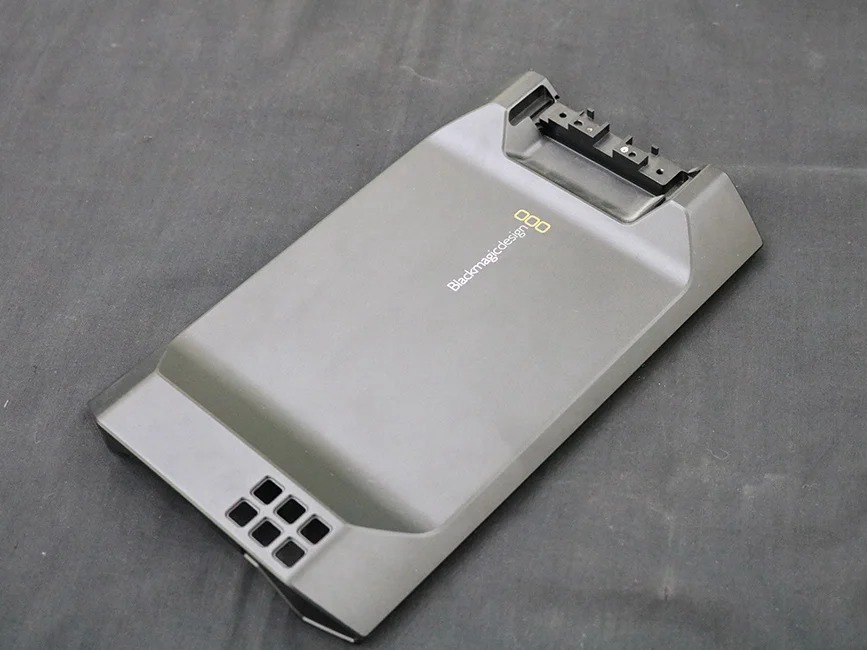

Case Study

Let's Start A New Project Today