Aerospace and Aviation Prototyping

Aerospace and Aviation Parts 3D Printing Service

Elevate your aerospace innovations with our 3D Printing Service! Lightweight components, intricate designs, and material efficiency ensure optimized performance. From rapid prototyping to production, we deliver precision-crafted parts tailored for aviation excellence. Your future is engineered today!

- Lighter Parts, Higher Efficiency!

- Complex Designs, Simplified Manufacturing!

- Faster Prototypes, Smarter Solutions!

3D Printing in Aerospace and Aviation

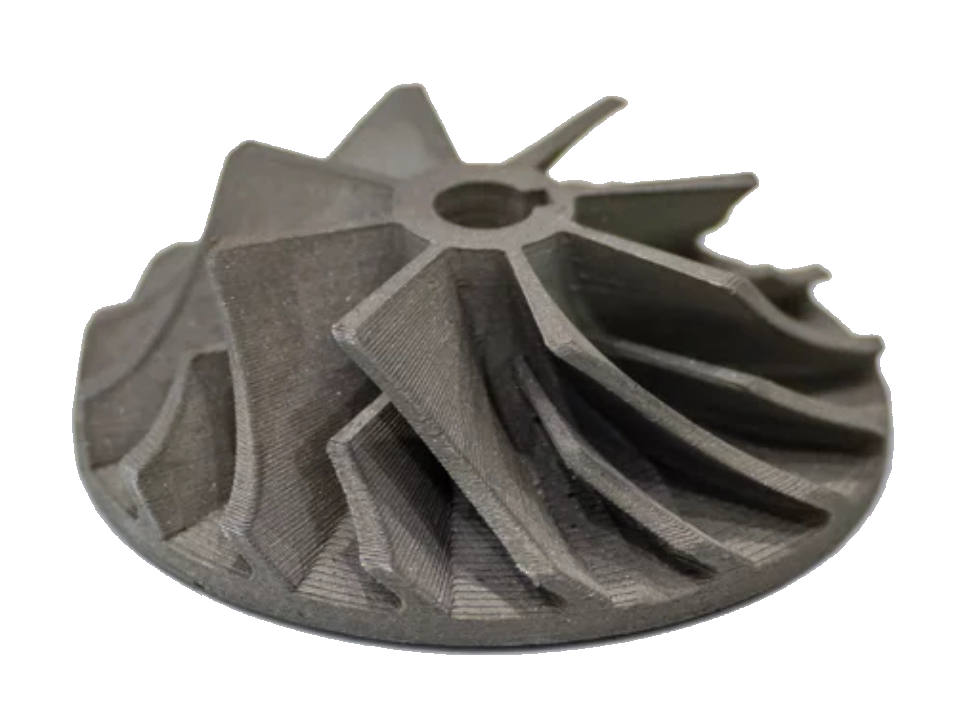

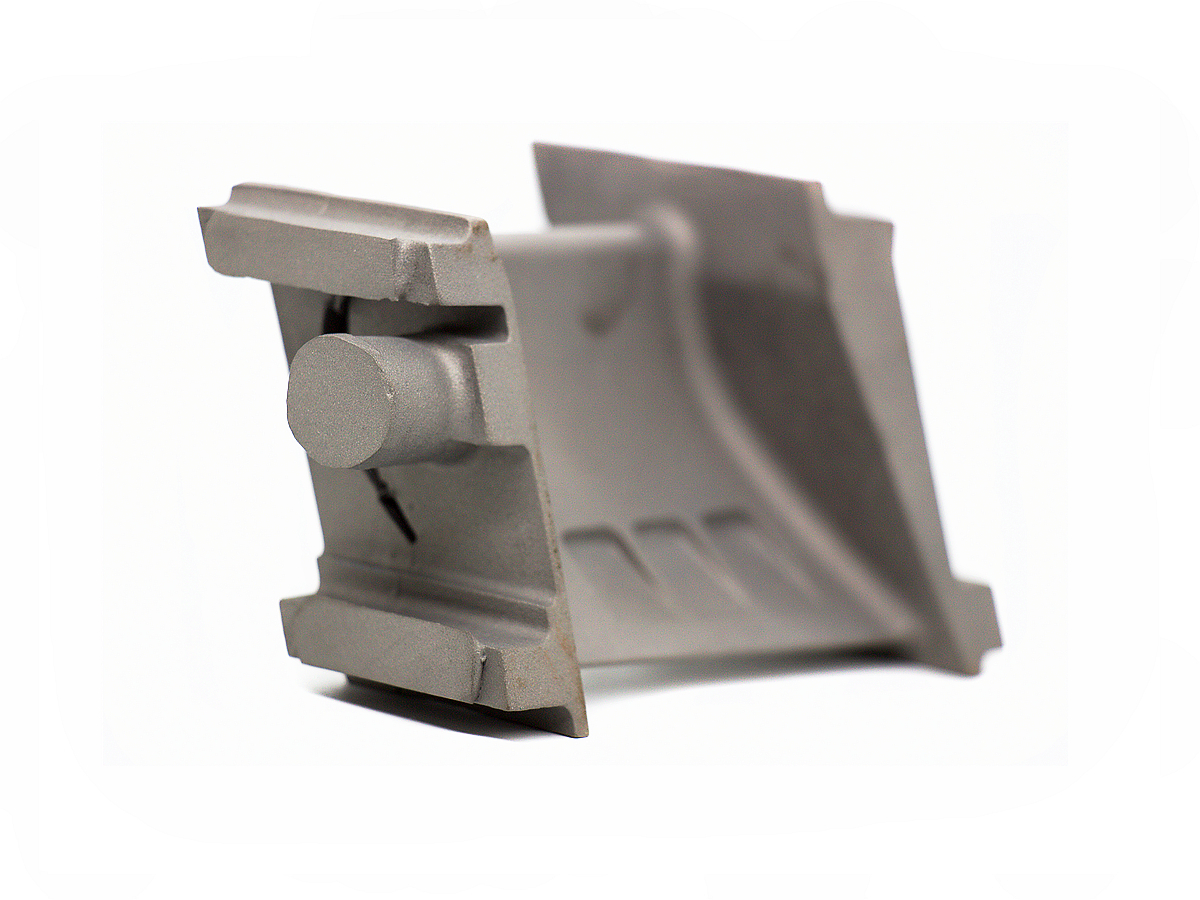

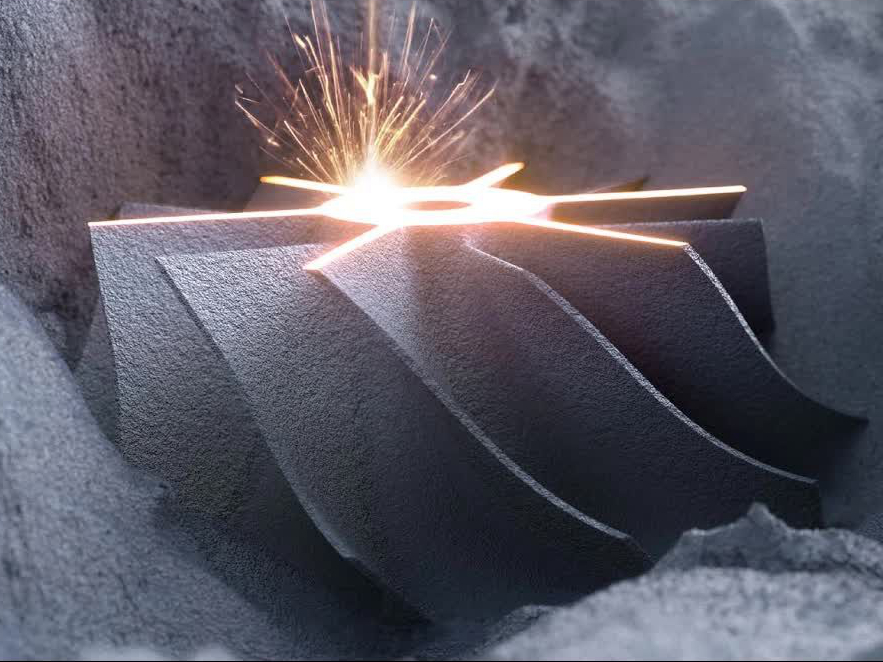

3D Printing in Aerospace and Aviation revolutionizes manufacturing by producing lightweight, high-strength components with complex geometries. Using materials like titanium, superalloys, and composites, it enhances fuel efficiency, reduces waste, and accelerates prototyping. Applications include engine parts, structural components, and cabin interiors, enabling cost-effective, high-performance solutions for modern aerospace engineering.

Benefits of 3D Printing In Aerospace and Aviation

3D printing in aerospace and aviation offers transformative benefits by reducing weight, consolidating parts, enhancing customization, and enabling cost-effective prototyping. These advantages improve fuel efficiency, reliability, and rapid development of advanced aerospace components.

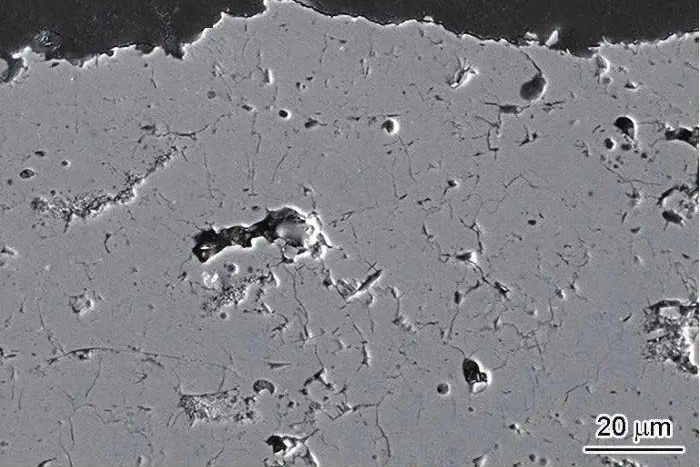

Material Solution for Aerospace and Aviation

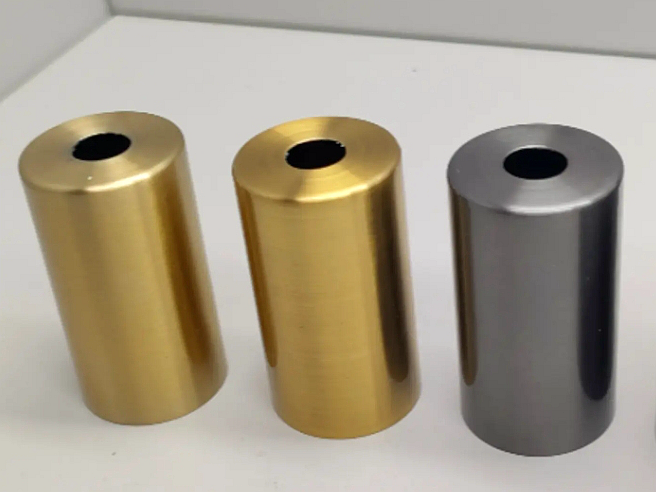

Our 3D Printing Material Solutions for Aerospace and Aviation parts manufacturing offer advanced options like Superalloy, Titanium Alloy, Ceramic, Stainless Steel, Carbon Steel, Copper, Plastics, and Resins, ensuring lightweight, durable, and high-performance components for cutting-edge applications.

Post Process for Aerospace and Aviation Parts

Our Post Process solutions for Aerospace and Aviation parts enhance performance, durability, and precision. From CNC machining to heat treatment and surface finishing, we deliver optimized, high-quality components tailored for the industry's demanding standards and applications.

3D Printing Process Solution

Our 3D Printing Process Solution offers cutting-edge technologies, including Material Extrusion, Powder Bed Fusion, and Directed Energy Deposition, enabling precision manufacturing, lightweight components, and optimized performance for aerospace, aviation, and other advanced industrial applications. Tailored to your unique needs.

Case Study

Let's Start A New Project Today